In the intricate world of manufacturing and supply chain management, success hinges on the ability to seamlessly navigate through a myriad of components, suppliers, and logistics challenges. In this article, we will delve into the critical aspects of component and supplier management, including the importance of part number cross references, supplier catalogs, and approved vendor lists. Furthermore, we will explore the complexities of logistics, transport, and shipping that play a pivotal role in ensuring goods reach their destination in a timely and efficient manner. Join us on this journey as we unravel the intricate web of operations that keeps the wheels of industry turning.

Understanding Part Number Cross References and Their Importance in Supplier Management

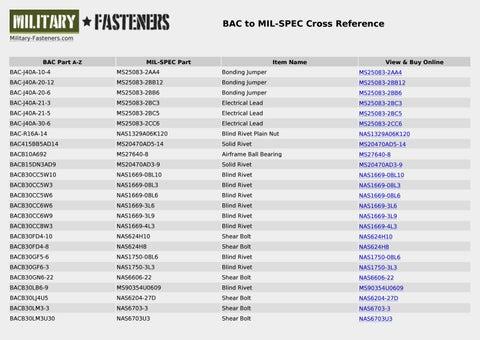

Understanding part number cross references is crucial in supplier management as it helps to ensure that the correct components are being sourced from the right suppliers. By having a comprehensive list of part number cross references, companies can easily identify alternative suppliers for specific components, reducing the risk of supply chain disruptions. This is especially important in industries where components have long lead times or are prone to shortages.

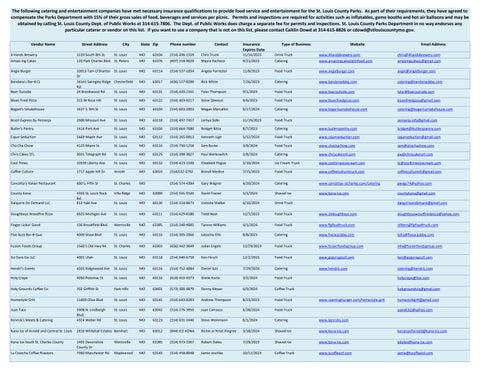

Supplier catalogs and approved vendor lists play a key role in component and supplier management. Supplier catalogs provide detailed information about the components offered by each supplier, making it easier for companies to compare prices, quality, and lead times. Approved vendor lists, on the other hand, help companies establish relationships with reliable suppliers who consistently meet quality and delivery standards. By leveraging part number cross references, supplier catalogs, and approved vendor lists, companies can optimize their supplier management processes and ensure a smooth flow of components for their operations.

Leveraging Supplier Catalogs to Optimize Purchasing Decisions

When it comes to optimizing purchasing decisions, component and supplier management play a crucial role. By leveraging part number cross references, supplier catalogs, and approved vendor lists, businesses can streamline their procurement process and ensure they are sourcing the right products from the right suppliers. This level of organization and accessibility to supplier information can help reduce the risk of errors, delays, and budget overruns, making purchasing decisions more efficient and effective.

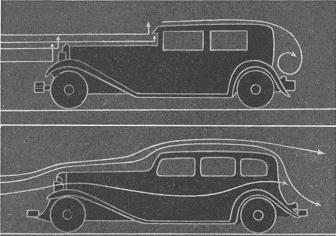

Another important aspect of optimizing purchasing decisions is focusing on logistics, transport, and shipping. By paying attention to the logistics of how products are sourced, transported, and delivered, businesses can improve efficiency, reduce costs, and minimize delays. Whether it’s negotiating favorable transportation rates, optimizing shipping routes, or implementing inventory management strategies, a well-managed logistics process can have a significant impact on the overall success of purchasing decisions.

Critical Role of Approved Vendor Lists in Supplier Management

In supplier management, approved vendor lists play a critical role in ensuring quality, reliability, and consistency in the components and materials used in production. By maintaining a comprehensive list of approved vendors, companies can streamline their procurement process, reduce risks of using subpar suppliers, and guarantee the integrity of their supply chain. This not only helps in maintaining high standards of product quality but also fosters stronger relationships with trusted suppliers.

Part number cross-references and supplier catalogs are essential tools that complement approved vendor lists in component and supplier management. These tools enable companies to quickly identify alternative vendors for specific parts, compare pricing and availability, and make informed decisions based on a variety of factors. Effective logistics, transport, and shipping strategies are also crucial in ensuring that components are delivered on time and in optimal condition, further enhancing the efficiency of supplier management processes.

Streamlining Logistics, Transport, and Shipping Processes for Efficient Operations

When it comes to , one key aspect to consider is component and supplier management. Having a system in place that allows for easy access to part number cross-references, supplier catalogs, and approved vendor lists can greatly improve efficiency and reduce the risk of errors. By ensuring that all necessary information is readily available, businesses can make quicker decisions, reduce downtime, and ultimately improve their bottom line.

Utilizing tools and technologies that centralize and organize component and supplier data can help businesses stay on top of inventory levels, pricing, and availability. By having a clear understanding of what components are needed, where they come from, and who supplies them, companies can better plan their logistics, transport, and shipping processes. This proactive approach can lead to smoother operations, reduced costs, and increased customer satisfaction.

To Wrap It Up

In conclusion, efficient component and supplier management is crucial for the smooth operation of any business. By utilizing part number cross references, supplier catalogs, and approved vendor lists, companies can streamline their procurement process and ensure a steady supply of high-quality materials. Additionally, logistics, transport, and shipping play a key role in getting products from suppliers to customers in a timely and cost-effective manner. With careful planning and attention to detail, businesses can optimize their supply chain processes and ultimately improve their bottom line. Remember, success in business often lies in the details.