In the fast-paced world of supply chain management, the key to success lies in efficient inventory management and seamless logistics operations. From perpetual inventory controls to physical inventory tools, there are countless methods and tools at your disposal to keep track of your stock. Additionally, the smooth running of transport and shipping processes is essential to ensuring timely deliveries and customer satisfaction. In this article, we will delve into the intricacies of these critical aspects of the industry and explore how they can be optimized for maximum efficiency.

Optimizing Inventory Management Techniques for Efficiency

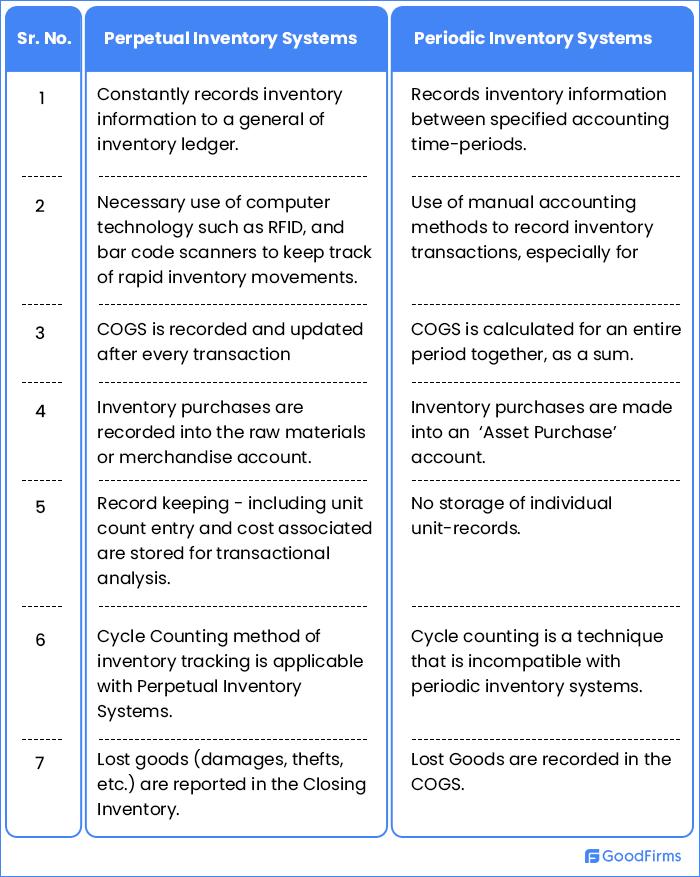

When it comes to , it is crucial to implement both perpetual and physical inventory controls. Perpetual inventory involves continuously updating stock levels in real-time through the use of technology like barcode scanners and inventory management software. This method allows businesses to have a clear view of their inventory at all times, facilitating accurate order fulfillment and reducing the risk of stockouts.

On the other hand, physical inventory controls involve conducting periodic manual counts of stock to cross-reference with the perpetual inventory system. This helps to identify discrepancies and ensure data accuracy. By combining both perpetual and physical inventory controls, businesses can maintain a more streamlined and accurate inventory management system, leading to improved efficiency and cost savings.

Implementing Perpetual Inventory Controls to Ensure Real-Time Accuracy

Implementing perpetual inventory controls is crucial for ensuring real-time accuracy in tracking your inventory levels. By utilizing tools such as barcode scanners and inventory management software, businesses can keep a constant tab on their stock levels and make informed decisions based on accurate data. With perpetual inventory controls in place, discrepancies and errors can be quickly identified and rectified, leading to smoother operations and better customer satisfaction.

One key benefit of perpetual inventory controls is the ability to minimize stockouts and overstock situations by providing real-time visibility into inventory levels. This not only helps in optimizing inventory levels but also in reducing carrying costs and improving overall efficiency. By implementing these controls, businesses can enhance their logistics and shipping processes, ensuring timely deliveries and maintaining customer trust. Embracing technology and automation in inventory management can streamline operations and drive growth in today’s fast-paced business environment.

Utilizing Logistics Solutions to Streamline Transport and Shipping Processes

When it comes to optimizing transport and shipping processes, effective inventory management is crucial. By implementing perpetual inventory controls and utilizing physical inventory tools, businesses can maintain accurate stock levels and ensure timely deliveries. This not only helps in reducing carrying costs but also minimizes the risk of stockouts and delays, thereby streamlining the overall logistics operations.

Furthermore, integrating logistics solutions like route optimization and real-time tracking systems can enhance visibility and control over shipments. This allows businesses to proactively address any issues that may arise during transit, leading to improved customer satisfaction and increased operational efficiency. By leveraging these technologies, companies can achieve a seamless flow of goods from production to delivery, ultimately driving growth and success in the competitive marketplace.

Maximizing Efficiency Through Physical Inventory Tools and Controls

When it comes to maximizing efficiency in inventory management, utilizing both perpetual and physical inventory controls and tools is crucial. Perpetual inventory allows for real-time tracking of stock levels, while physical inventory checks ensure accuracy and accountability. By implementing a combination of these controls, businesses can optimize their inventory processes and avoid costly errors.

Logistics, transport, and shipping are integral parts of a successful inventory management strategy. Efficient transportation of goods can help streamline the supply chain and reduce lead times. By utilizing shipping optimization tools and implementing effective logistics management practices, businesses can ensure smooth operations and timely delivery of products to customers.

Closing Remarks

In conclusion, effective inventory management is crucial for any business looking to optimize their supply chain operations. By implementing perpetual and physical inventory controls and utilizing logistics tools for transport and shipping, companies can streamline their processes, reduce costs, and improve overall efficiency. Whether it’s tracking inventory levels in real-time or ensuring timely deliveries, the right tools and practices can make all the difference. So, invest in the right inventory management systems and logistics solutions to take your business to the next level. Thank you for reading!