In the ever-evolving landscape of supply chain management, the concept of total obsolescence has emerged as a crucial consideration for businesses looking to streamline their inventory processes. From raw materials to finished goods, the logistics of storing and transporting inventory poses unique challenges that require careful planning and innovation. In this article, we will delve into the intricacies of total obsolescence for raw material, work-in-progress (WIP), and finished goods inventory, exploring the vital role it plays in the efficiency and sustainability of modern supply chains.

Understanding Total Obsolescence in Inventory Management

Total obsolescence in inventory management is a critical issue that affects various aspects of a business, including raw material, work-in-progress (WIP), and finished goods inventory. Understanding the concept of total obsolescence is crucial for businesses to effectively manage their inventory and prevent unnecessary losses. When inventory items become obsolete, they can no longer be sold or used in production, leading to financial losses and disruptions in the supply chain.

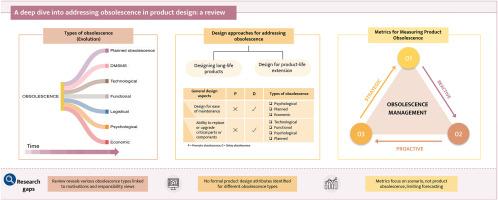

There are several factors that can contribute to total obsolescence in inventory management, such as changes in consumer demand, technological advancements, and product shelf life. By identifying these factors and implementing strategies to mitigate the risk of total obsolescence, businesses can minimize their losses and optimize their inventory management processes. Utilizing tools like inventory tracking systems and demand forecasting can help businesses better anticipate and prevent total obsolescence in their inventory.

Maximizing Efficiency in Logistics Operations

One key aspect to consider when it comes to is the management of raw material, work in progress (WIP), and finished goods inventory. Total obsolescence of these inventory types can significantly impact the overall efficiency of a supply chain. By implementing effective inventory management strategies, businesses can minimize the risk of obsolescence and optimize their operations.

Some ways to achieve total obsolescence for raw material, WIP, and finished goods inventory include:

- Regular Inventory Audits: Conducting regular audits to identify obsolete items and take necessary actions to liquidate or repurpose them.

- Implementing Just-in-Time (JIT) Inventory Systems: Adopting JIT practices can help reduce excess inventory levels and minimize the risk of obsolescence.

- Utilizing Technology: Leveraging inventory management software and automation tools can improve accuracy, visibility, and control over inventory levels.

Strategies for Minimizing Obsolescence Risks in Shipping and Transport

One effective strategy for minimizing obsolescence risks in shipping and transport is to implement a robust inventory management system that closely monitors the levels of raw materials, work in progress (WIP), and finished goods. By regularly reviewing and analyzing inventory data, businesses can identify potential obsolescence risks early on and take proactive measures to mitigate them. This may involve adjusting production schedules, reducing order quantities, or liquidating excess inventory through discounts or promotions.

Another key strategy is to establish strong partnerships with suppliers and distributors to ensure a steady flow of goods and materials that align with market demand. By fostering open communication and collaboration, businesses can better anticipate changes in consumer preferences, industry trends, and regulatory requirements that may impact the relevance and value of their inventory. Additionally, leveraging technology such as data analytics and real-time tracking systems can provide valuable insights into inventory turnover rates, demand forecasting, and supply chain efficiencies.

Incorporating Technology for Effective Inventory Management Strategies

One effective strategy for managing inventory obsolescence is to implement technology-driven solutions that can help track and monitor raw material, work-in-progress (WIP), and finished goods. By utilizing advanced inventory management systems, businesses can have real-time visibility into their inventory levels, expiration dates, and demand forecasts.

Some key ways technology can help prevent total obsolescence in inventory include:

- Automated alerts for impending expiration dates or obsolete inventory

- Data analytics to predict demand and optimize inventory levels

- Integration with suppliers for seamless replenishment and JIT (Just-In-Time) inventory management

- Barcoding and RFID technology for accurate tracking and inventory control

Key Takeaways

In conclusion, the concept of total obsolescence for raw material, work-in-progress, and finished goods inventory may seem daunting, but it is also a necessary part of optimizing supply chain operations. By embracing modern technologies and innovative logistics strategies, companies can minimize waste, reduce costs, and improve overall efficiency. As we look towards the future of inventory management, let us continue to explore new ways to streamline processes and adapt to the ever-changing demands of the global marketplace. Only by staying ahead of the curve can we truly achieve success in today’s fast-paced world of commerce.