In the ever-evolving world of logistics, the key to success lies in effective collaboration and strategic planning. Enter Collaborative Planning, Forecasting, and Replenishment (CPFR) - a sophisticated approach that revolutionizes how businesses manage their supply chain operations. In this article, we delve into the intricacies of CPFR and explore how this innovative framework is reshaping the landscape of transportation, shipping, and overall logistics management.

Heading 1: Enhancing Supply Chain Efficiency through Collaborative Planning

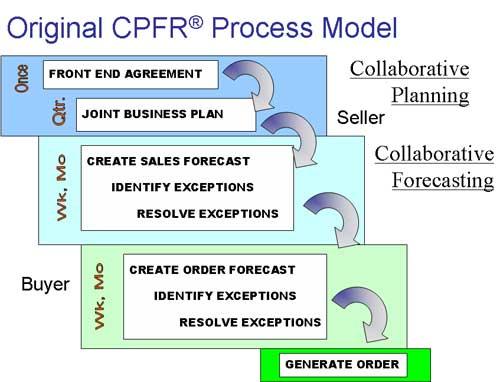

Collaborative Planning, Forecasting, and Replenishment (CPFR) is a powerful strategy that can significantly enhance supply chain efficiency. By bringing together key stakeholders such as suppliers, manufacturers, and retailers, CPFR enables real-time collaboration and information sharing to improve forecasting accuracy and reduce inventory levels. This ultimately leads to a streamlined and more responsive supply chain, resulting in cost savings and increased customer satisfaction.

With CPFR, organizations can benefit from improved demand planning, enhanced inventory management, and optimized replenishment processes. By leveraging technology and data analytics, companies can make more informed decisions and adapt quickly to changing market conditions. By fostering greater transparency and trust among partners, CPFR helps to build stronger relationships and create a more resilient supply chain ecosystem.

Heading 2: Leveraging Forecasting Techniques for Effective inventory management

One of the key strategies in effective inventory management is leveraging advanced forecasting techniques to optimize inventory levels and ensure product availability. By implementing Collaborative Planning, Forecasting, and Replenishment (CPFR) practices, businesses can enhance their supply chain efficiency and reduce stockouts and overstock situations.

With CPFR, companies can collaborate with suppliers, distributors, and retailers to share demand forecasts, sales data, and inventory levels. This collaborative approach allows for better demand planning, improved order accuracy, and increased visibility across the supply chain. By incorporating advanced forecasting models and data analytics, businesses can make informed decisions to streamline their inventory management processes and drive overall business success.

Heading 3: Streamlining Replenishment Processes for Optimal Inventory Levels

Implementing Collaborative Planning, Forecasting, and Replenishment (CPFR) can revolutionize the way businesses manage their inventory levels. By fostering collaboration between suppliers, manufacturers, and retailers, CPFR streamlines replenishment processes to ensure optimal inventory levels are maintained. This leads to reduced stockouts, minimized excess inventory, and improved overall supply chain efficiency.

Through CPFR, organizations can leverage real-time data and insights to accurately forecast demand, plan production schedules, and synchronize replenishment activities. By working together to create a unified inventory strategy, stakeholders can reduce lead times, improve order accuracy, and enhance customer satisfaction. With CPFR, businesses can achieve a competitive edge in today’s fast-paced market environment.

Heading 4: Integrating CPFR Strategies into Transport and Shipping Logistics

Collaborative Planning, Forecasting, and Replenishment (CPFR) strategies have revolutionized the way businesses plan their transport and shipping logistics. By integrating CPFR into these operations, companies can improve efficiency, reduce costs, and enhance customer satisfaction. Through shared information and collaborative decision-making, organizations can streamline their supply chain processes and ensure that products are delivered on time and in the most cost-effective manner.

- Improved Communication: CPFR fosters communication between suppliers, manufacturers, and distributors, leading to better coordination and alignment of objectives.

- Enhanced Forecasting: By sharing sales data and demand forecasts, companies can better predict market trends and adjust their transportation and shipping logistics accordingly.

| Benefits of Integrating CPFR into Transport and Shipping Logistics |

|---|

| Cost reduction |

| Increased efficiency |

| Real-time tracking |

Wrapping Up

In conclusion, collaborative planning, forecasting, and replenishment (CPFR) is a proven method for businesses to optimize their supply chain processes and enhance efficiency in logistics, transport, and shipping. By fostering partnerships with suppliers, retailers, and other stakeholders, companies can streamline operations, reduce costs, and ultimately deliver better service to their customers. Embracing CPFR not only improves inventory management and demand forecasting but also fosters greater collaboration and communication throughout the supply chain. So, whether you’re a small business or a multinational corporation, consider implementing CPFR to stay ahead in today’s competitive market. Join the collaborative revolution and revolutionize the way you do business!