In the chaotic world of logistics, where every movement and decision can make or break a company’s success, the importance of centralized inventory control cannot be understated. From managing the flow of goods to optimizing transportation routes, centralized inventory control is the backbone of any successful shipping operation. Join us as we delve into the world of centralized inventory control and discover how this essential tool can revolutionize the way you do business.

The importance of centralized inventory control in supply chain management

Having a centralized inventory control system in place is essential for effective supply chain management. By centralizing inventory control, companies can streamline their operations and improve overall efficiency. This allows for better tracking of inventory levels, reducing the risk of stockouts and overstocking. With a centralized system, companies can more easily identify trends and forecast demand, leading to better inventory management decisions.

Centralized inventory control also helps to reduce costs by minimizing storage and carrying expenses. By having a clear view of inventory levels across all facilities, companies can optimize their supply chain and avoid unnecessary stockpiling. Additionally, centralized inventory control allows for better coordination between different departments, ensuring that all teams are working towards the same goals. Overall, a centralized inventory control system is crucial for maximizing efficiency and minimizing costs in supply chain management.

Logistics optimization through centralized inventory control

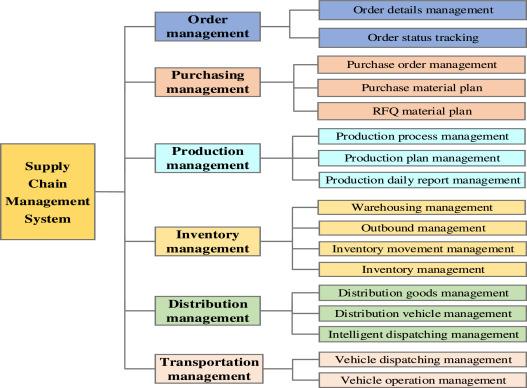

Efficient logistics operations are vital for businesses looking to streamline their processes and reduce costs. By implementing centralized inventory control, companies can optimize their supply chain management and improve overall efficiency. Centralized inventory control involves consolidating all inventory data and management in one centralized system, allowing for better coordination and decision-making across all locations.

With centralized inventory control, companies can benefit from:

- Improved visibility: Having a centralized system allows for real-time visibility into inventory levels, reducing the risk of stockouts or overstocking.

- Cost savings: By optimizing inventory levels and reducing excess stock, companies can save costs on storage and carrying expenses.

- Enhanced forecasting: Centralized inventory control enables better forecasting and planning, leading to more accurate inventory replenishment and reduced lead times.

Enhancing shipping efficiency with centralized inventory management strategies

Managing inventory efficiently is critical for any business, especially in the shipping and logistics industry. By implementing centralized inventory control systems, companies can streamline their operations, reduce costs, and improve overall efficiency. One key benefit of centralized inventory management is the ability to track stock levels in real-time, allowing for better inventory planning and forecasting.

Centralized inventory control also helps companies optimize their warehouse space, minimize stockouts, and prevent overstocking. With a centralized system in place, businesses can easily manage multiple warehouses and distribution centers, ensuring that products are always available when needed. By leveraging technology and data analytics, companies can gain valuable insights into their inventory levels and make informed decisions to enhance their shipping processes.

Recommendations for implementing centralized inventory control in transport and shipping operations

Implementing centralized inventory control in transport and shipping operations is crucial for optimizing efficiency and reducing costs. To successfully implement a centralized inventory control system, consider the following recommendations:

- Integration of Systems: Ensure seamless integration of inventory management systems with transportation and shipping systems to streamline operations.

- Real-time Tracking: Implement real-time tracking technology to monitor inventory levels and shipments accurately and efficiently.

- Automation: Utilize automation tools to automate inventory replenishment, order processing, and shipping documentation.

| Recommendation | Importance |

|---|---|

| Integration of Systems | High |

| Real-time Tracking | Medium |

| Automation | High |

By following these recommendations, companies can enhance their logistical operations, improve inventory accuracy, and enhance customer satisfaction. Implementing centralized inventory control in transport and shipping operations will ultimately lead to increased efficiency and profitability in the long run.

Concluding Remarks

In conclusion, centralized inventory control is a crucial component of a successful logistics operation, ensuring efficient transportation and timely shipping of goods. By centralizing inventory management, companies can streamline their supply chain processes, reduce costs, and improve overall productivity. With the right tools and strategies in place, businesses can optimize their inventory control and stay ahead of the competition in today’s fast-paced market. Embracing centralized inventory control is the first step towards achieving operational excellence and meeting customer demands in the ever-evolving world of logistics and transportation.