In the intricate world of manufacturing, efficiency is key. Make to Order (Manufacture to Order) logistics, transport, and shipping play a crucial role in ensuring products are delivered to customers swiftly and seamlessly. This article will delve into the various nuances of this process, exploring how businesses can optimize their operations and enhance customer satisfaction through strategic planning and innovative solutions. Join us as we unravel the intricacies of Make to Order logistics and discover the magic behind the seamless delivery of products from factory to doorstep.

The Benefits of Make to Order Manufacturing

One of the biggest advantages of Make to Order manufacturing is the ability to customize products according to the specific needs of each customer. This means that businesses can tailor their products to meet the exact requirements of individual clients, leading to higher customer satisfaction and loyalty. By producing goods only when an order is received, companies can also reduce excess inventory and waste, resulting in cost savings and a more environmentally friendly operation.

Another benefit of Make to Order manufacturing is the flexibility it provides in responding to changing market demands. With this approach, businesses can quickly adjust their production schedule to accommodate rush orders or design changes, ensuring that they can meet tight deadlines and stay competitive in a fast-paced industry. Additionally, Make to Order manufacturing can help companies minimize the risk of overproduction and obsolescence, as products are created in response to real-time demand rather than forecasts.

Strategies for Streamlining Make to Order Logistics

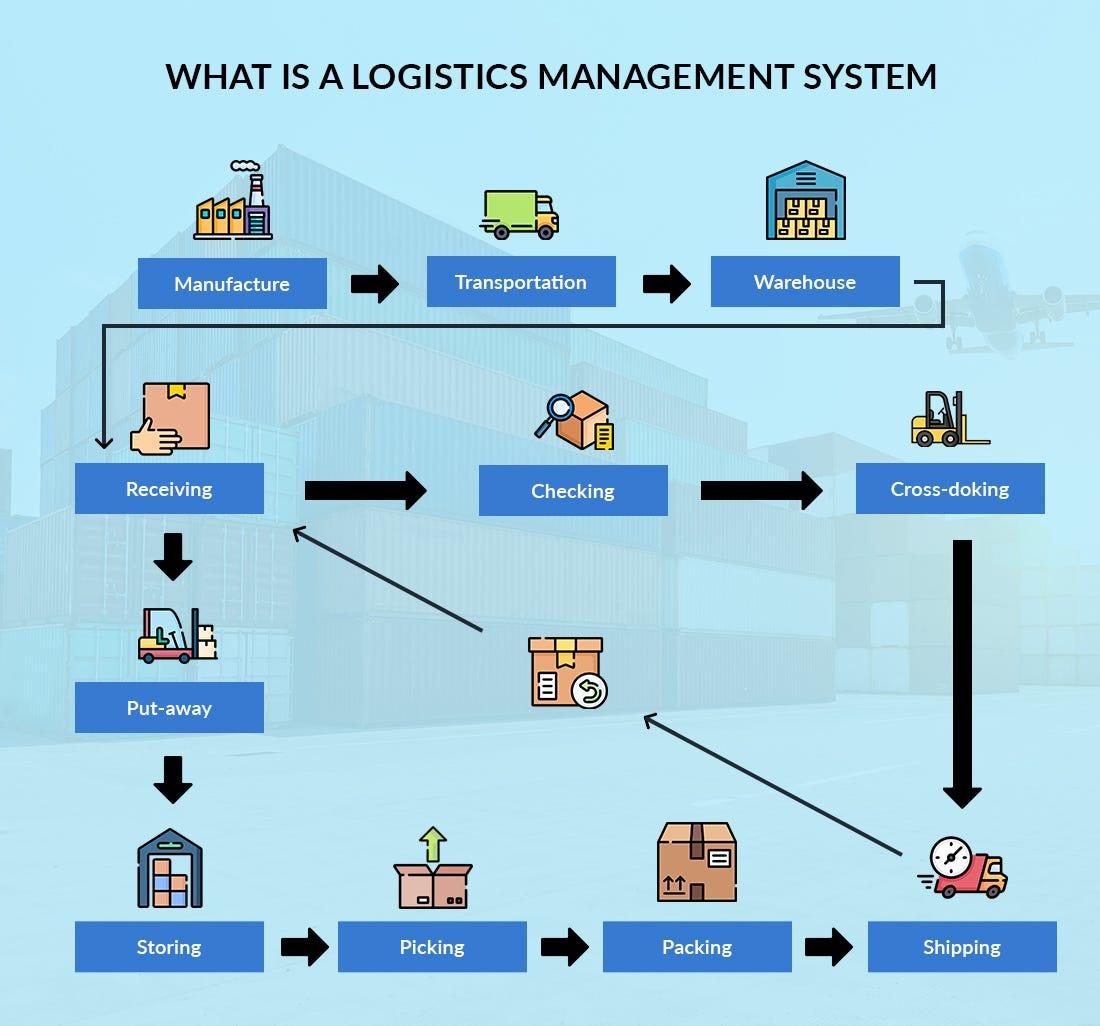

When it comes to streamlining Make to Order logistics, there are several strategies that businesses can implement to improve efficiency and reduce costs. One key strategy is to optimize transportation routes to minimize delivery times and reduce shipping costs. By using advanced routing software and data analytics, companies can identify the most efficient routes for delivering products to customers.

Another important strategy is to improve communication and collaboration between all parties involved in the Make to Order process, including suppliers, manufacturers, and distributors. By using cloud-based platforms and digital tools, companies can streamline communication, track orders in real-time, and quickly resolve any issues that may arise. This enhanced visibility and communication can help to prevent delays and ensure that products are delivered to customers on time.

Optimizing Shipping Processes for Make to Order Products

When it comes to , there are several key considerations that businesses need to take into account. From streamlining logistics to enhancing transport efficiency, these factors play a crucial role in ensuring timely delivery and customer satisfaction.

One effective strategy is to leverage advanced shipping software solutions that enable real-time tracking and monitoring of orders. This not only helps in improving visibility across the supply chain but also allows for proactive management of any potential delays or disruptions. Additionally, establishing strong partnerships with reliable carriers and third-party logistics providers can further streamline the shipping process, ensuring that make to order products reach their destination in a timely manner.

Key Considerations for Transporting Make to Order Goods

When it comes to transporting make to order goods, there are several key considerations that need to be taken into account to ensure a smooth and efficient process. One of the most important factors to consider is the lead time for production. Since make to order goods are manufactured based on specific customer requirements, it is crucial to have a clear understanding of the production timeline to coordinate transportation logistics accordingly.

Another important consideration is the mode of transportation. Depending on the size and weight of the goods, as well as the distance they need to travel, different transportation methods may be more suitable. Whether it’s by truck, rail, air, or sea, choosing the right mode of transportation can help optimize costs and delivery times. Additionally, factors such as packaging, handling instructions, and tracking capabilities should also be carefully planned to ensure the safe and timely delivery of make to order goods.

Concluding Remarks

In conclusion, Make to Order (Manufacture to Order) logistics, transport, and shipping play a crucial role in ensuring that products are delivered to customers in a timely and efficient manner. By customizing products to meet the specific needs of individual customers, businesses can increase customer satisfaction and improve the overall efficiency of their supply chain. It is important for companies to carefully consider their logistics strategies and partner with reliable transportation and shipping providers to ensure a successful Make to Order process. By focusing on personalized, on-demand production, businesses can differentiate themselves in the marketplace and build long-lasting relationships with their customers. Thank you for reading!