In the intricate dance of global trade, materials planning plays a vital role in ensuring the smooth movement of goods from production to delivery. From logistics to transport to shipping, every step must be meticulously coordinated to keep the supply chain flowing seamlessly. Join us as we delve into the world of materials planning, where precision and strategy intersect to drive commerce forward.

Optimizing Materials Planning for Efficient Supply Chain Management

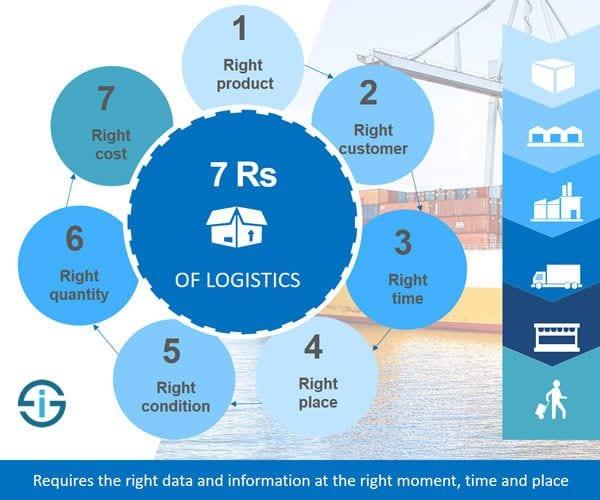

Efficient materials planning is crucial for the success of any supply chain management strategy. By optimizing the process of forecasting and procuring materials, businesses can minimize waste, reduce costs, and improve overall efficiency. One key aspect of materials planning is to ensure that the right materials are available at the right time and in the right quantities. This requires close collaboration between procurement, production, and logistics teams to ensure seamless supply chain operations.

Transportation plays a vital role in materials planning, as it directly impacts lead times, costs, and overall customer satisfaction. By carefully selecting transportation modes and routes, businesses can streamline their shipping processes and reduce delays. Utilizing advanced technologies such as GPS tracking and real-time monitoring can help improve visibility and control over the entire shipping process, allowing for better decision-making and faster response times to unexpected events. Implementing sustainable transport practices can also contribute to cost savings and environmental preservation, aligning with modern consumers’ increasing focus on eco-friendly operations.

Implementing Innovative Logistics Strategies to Streamline Operations

One innovative logistics strategy that can greatly streamline operations is implementing just-in-time (JIT) inventory management. With JIT, materials and goods are only ordered and received when they are needed for production, reducing excess inventory and minimizing storage costs. This lean approach not only improves efficiency but also helps in reducing waste and optimizing cash flow.

Another effective strategy is utilizing advanced tracking and monitoring technologies such as RFID and GPS. These tools provide real-time visibility into the movement of materials and products throughout the supply chain, allowing for better decision-making and improved coordination between various stakeholders. By leveraging these technologies, logistics managers can enhance efficiency, increase accuracy, and ensure timely delivery of goods to customers.

Maximizing Shipping Efficiency through Effective Transport Management

Effective transport management plays a crucial role in maximizing shipping efficiency and ensuring timely delivery of goods. By implementing strategic materials planning, logistics teams can streamline operations, reduce costs, and improve overall customer satisfaction. One key aspect of transport management is route optimization, which involves planning the most efficient routes to minimize fuel consumption and reduce transit times.

Utilizing advanced tracking and monitoring technologies can also enhance transport management by providing real-time visibility into shipments. This allows logistics teams to proactively address any potential delays or issues that may arise during transit. By adopting a data-driven approach to transport management, companies can make informed decisions that optimize shipping efficiency and improve overall supply chain performance.

Key Recommendations for Improving Material Planning and Logistics in Shipping Operations

When it comes to improving material planning and logistics in shipping operations, it is important to focus on efficiency and accuracy. One key recommendation is to invest in advanced technology to streamline processes and optimize resource utilization. Utilizing automated systems for inventory management and tracking can help reduce errors and improve overall efficiency.

Another recommendation is to establish strong communication channels between different departments involved in material planning and logistics. Effective collaboration and coordination between teams can help prevent delays and ensure smooth operations. It is also important to regularly review and update processes to adapt to changing market conditions and customer demands. By implementing these key recommendations, shipping operations can enhance their material planning and logistics to meet the challenges of the modern shipping industry.

In Conclusion

In conclusion, materials planning plays a crucial role in ensuring smooth logistics, efficient transportation, and timely shipping of goods. By carefully analyzing demand, inventory levels, and production capabilities, businesses can optimize their supply chain processes and minimize costs. With the right strategies in place, companies can improve customer satisfaction, reduce lead times, and ultimately achieve greater success in the competitive marketplace. So remember, when it comes to materials planning, the key is to think ahead, stay organized, and always be ready to adapt to changing circumstances. Only then can you truly unlock the potential for growth and profitability in your operations.