In the complex world of Manufacturing Resource Planning (MRP-II), logistics, transport, and shipping play a crucial role in ensuring the seamless flow of materials and products. From the intricate coordination of supply chains to the timely delivery of goods, the interplay of these elements is essential in driving efficiency and maximizing productivity. Join us as we delve into the intricate web of MRP-II logistics and explore the key mechanisms that keep the manufacturing industry moving forward.

Understanding the Role of MRP-II in Optimizing Logistics Processes

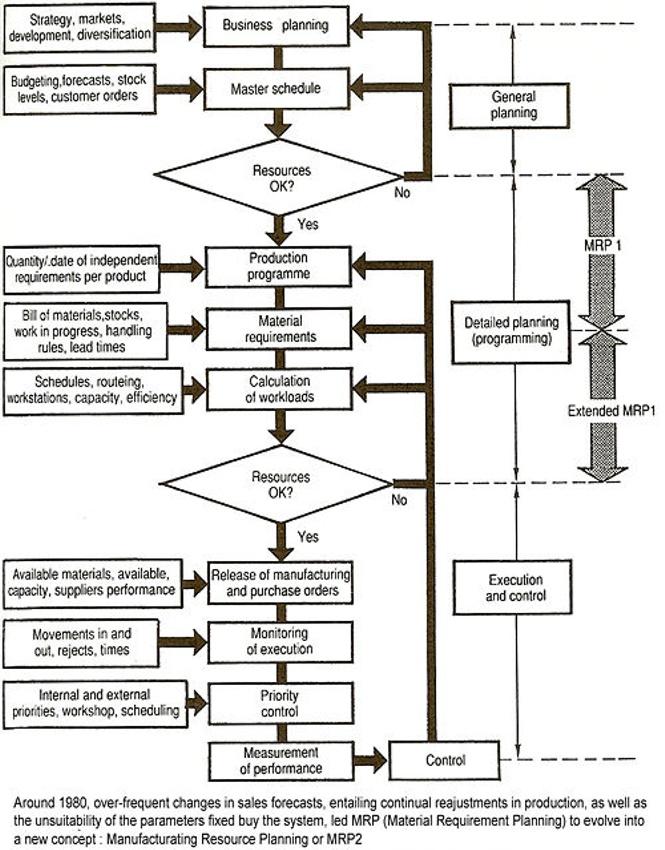

Manufacturing Resource Planning (MRP-II) plays a crucial role in optimizing logistics processes within a manufacturing environment. By integrating production planning, inventory management, and scheduling, MRP-II helps streamline operations and improve efficiency. This powerful tool allows businesses to make informed decisions about material requirements, production schedules, and resource allocation, ultimately leading to cost savings and improved customer satisfaction.

With MRP-II, companies can better manage their supply chain and ensure that materials are available when and where they are needed. By automating and centralizing data, organizations can reduce lead times, minimize stockouts, and improve forecasting accuracy. This results in smoother logistics operations, reduced inventory carrying costs, and increased overall productivity. By leveraging the capabilities of MRP-II, businesses can stay ahead of the competition and deliver products to customers faster and more efficiently.

Implementing Effective Strategies for Efficient Transport Management

is crucial for any business looking to streamline operations and reduce costs. One such strategy that has been proven to enhance transport management is Manufacturing Resource Planning (MRP-II). MRP-II integrates various production processes with logistics, transport, and shipping functions, allowing businesses to optimize their supply chain and improve overall efficiency.

With MRP-II, businesses can better plan and coordinate their transport activities, ensuring timely deliveries and reducing idle time. By utilizing advanced data analytics and real-time tracking, companies can proactively address any potential issues that may arise during transportation, leading to smoother operations and increased customer satisfaction. Additionally, MRP-II helps businesses identify areas for improvement, such as optimizing routes, reducing fuel consumption, and minimizing carbon emissions, ultimately contributing to a more sustainable transport management approach.

Maximizing Shipping Efficiency through Advanced MRP-II Integration

When it comes to maximizing shipping efficiency, integrating Manufacturing Resource Planning (MRP-II) into your logistics process can be a game changer. By combining advanced MRP-II technology with your shipping operations, you can streamline your supply chain, reduce costs, and improve overall productivity. With real-time data and forecasting capabilities, MRP-II can help you better plan and execute your shipping strategy.

By integrating MRP-II into your shipping process, you can optimize inventory levels, reduce lead times, and improve order accuracy. This means faster delivery times, lower shipping costs, and increased customer satisfaction. With MRP-II, you can track shipments, monitor inventory levels, and make informed decisions to ensure timely deliveries. Take advantage of this advanced technology to revolutionize your shipping efficiency and stay ahead of the competition.

In Conclusion

In conclusion, Manufacturing Resource Planning (MRP-II) plays a crucial role in optimizing logistics, transportation, and shipping processes within manufacturing industries. By utilizing MRP-II effectively, companies can streamline operations, reduce costs, and improve overall efficiency. With the constantly evolving landscape of technology and supply chain management, staying abreast of the latest advancements in MRP-II is essential for businesses looking to maintain a competitive edge in today’s global marketplace. Embracing innovation and incorporating best practices in logistics and shipping will undoubtedly lead to success and growth in the ever-changing world of manufacturing.