In the world of logistics, the concept of “Last In First Out” (LIFO) is a strategy that has been gaining popularity in recent years. This innovative approach to managing the flow of goods through the supply chain is transforming the way companies handle transport and shipping. In this article, we will delve into the intricacies of LIFO logistics and explore how this method is revolutionizing the industry. From optimizing inventory control to streamlining distribution processes, LIFO is shaping the future of logistics in a dynamic and efficient manner. So, buckle up as we take you on a journey through the world of LIFO logistics – where the last one in is the first one out.

Understanding the Last In First Out (LIFO) Inventory Management System

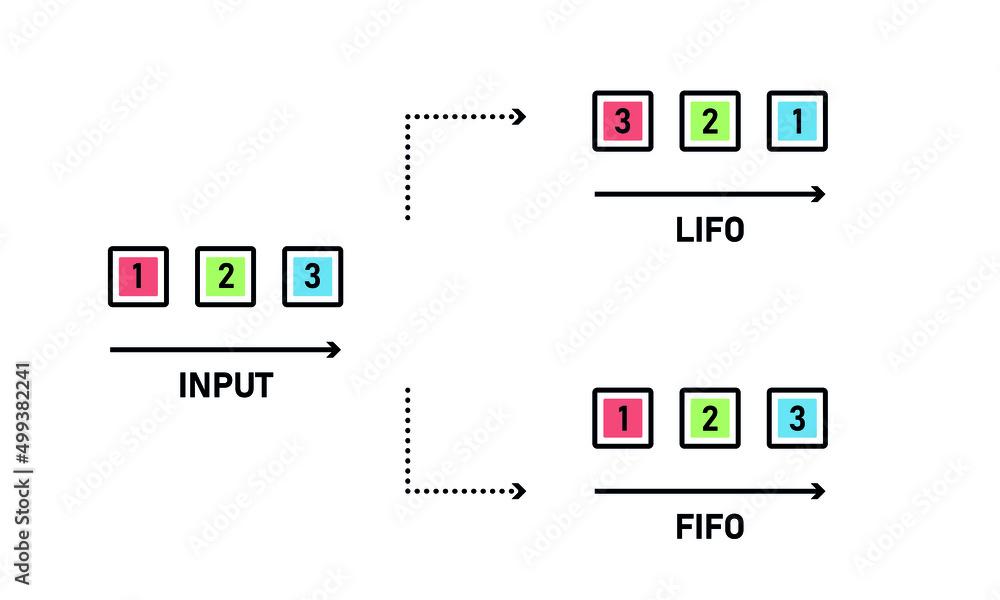

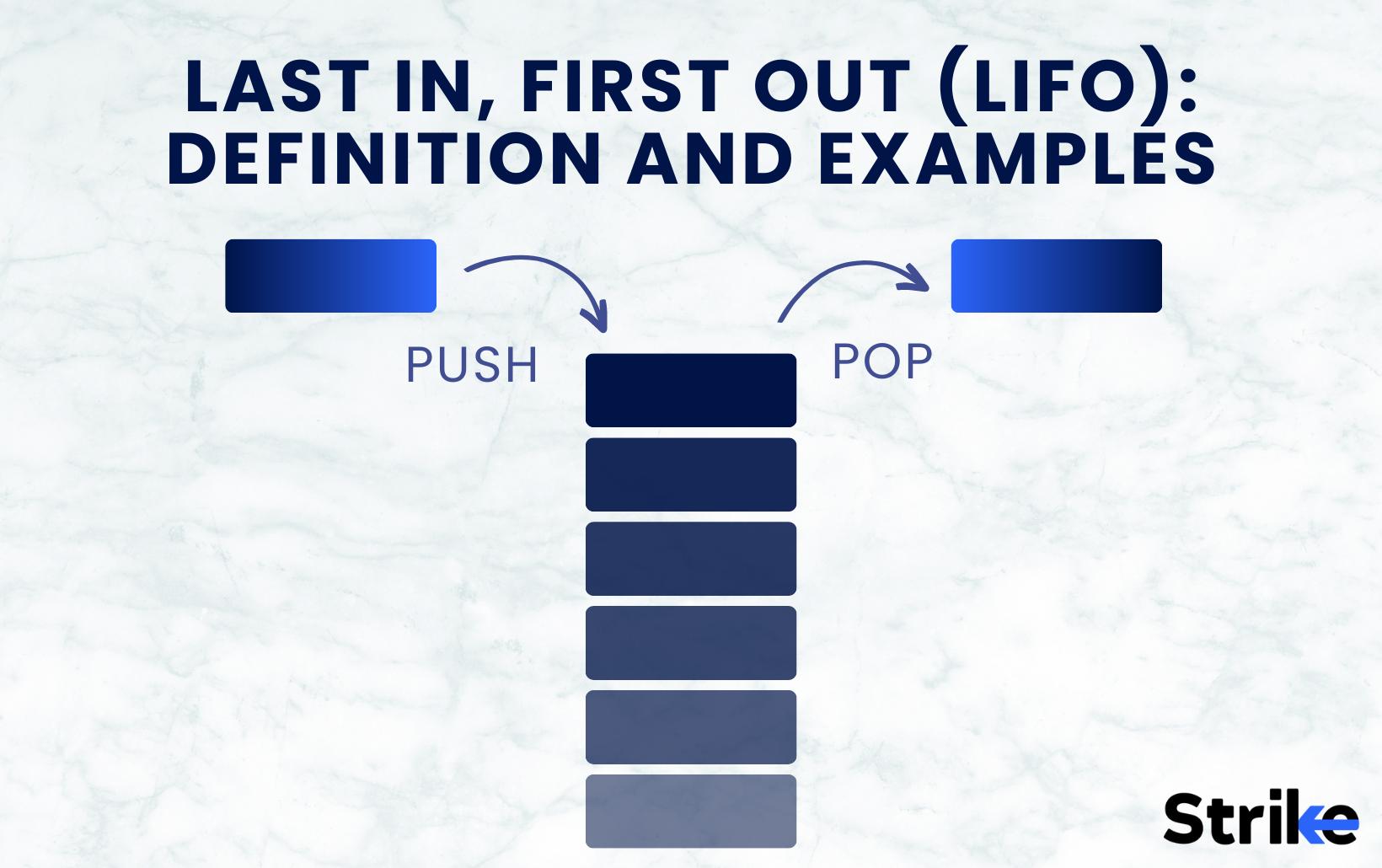

When it comes to managing inventory, the Last In First Out (LIFO) system is a popular method used by many businesses. This system operates under the assumption that the last items added to the inventory are the first to be sold or used. Understanding how LIFO works can help businesses streamline their inventory management processes and optimize their supply chain.

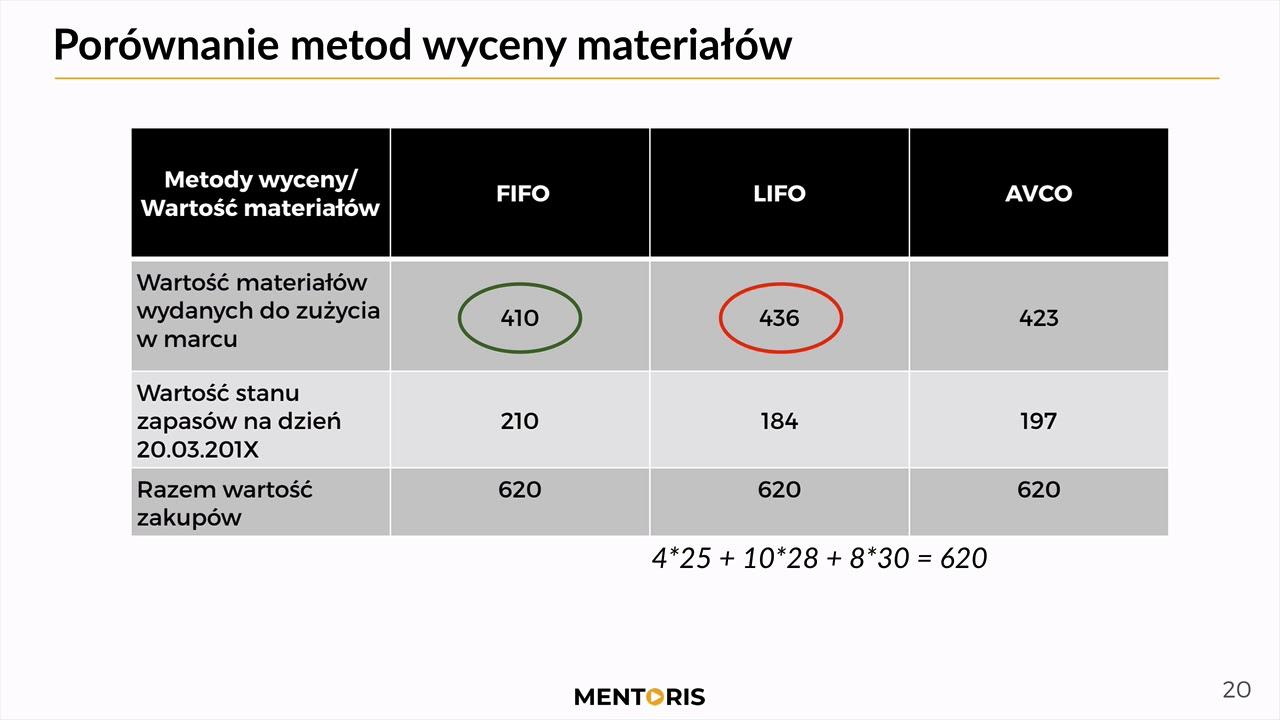

One of the main advantages of using the LIFO system is that it can help companies minimize their tax liabilities by reducing their taxable income. By valuing their inventory based on the most recent prices, businesses can lower their reported profits and ultimately pay less in taxes. Additionally, the LIFO system can also help companies adapt to inflationary pressures by reflecting current market prices in their inventory valuation.

Implementing LIFO in Logistics for Improved Efficiency

Implementing the Last In First Out (LIFO) system in logistics can greatly improve efficiency and streamline operations in the transportation and shipping industries. By organizing inventory so that the newest items are used or shipped first, companies can reduce waste, minimize storage costs, and enhance overall productivity. This method is particularly beneficial for perishable goods or products with expiration dates, ensuring that the freshest items are always being distributed.

With the LIFO approach, businesses can optimize their warehouse space, as it eliminates the need to constantly rearrange inventory to access older items. This system also allows for quicker retrieval of goods, reducing turnaround times for orders and increasing customer satisfaction. By strategically implementing LIFO in logistics, companies can enjoy a more efficient supply chain process and ultimately improve their bottom line.

Challenges and Solutions in LIFO Shipping Strategies

One of the main challenges in implementing a Last In First Out (LIFO) shipping strategy is the risk of products becoming outdated or spoiled before they are shipped out. This can result in significant financial losses for companies, as they are forced to dispose of unsellable inventory. To combat this issue, businesses can implement better inventory management systems that prioritize the rotation of goods based on their expiration dates or shelf life.

<p>Another obstacle in LIFO shipping strategies is the potential for delays in the delivery of goods, especially when relying on suppliers to ship products in a timely manner. To address this challenge, companies can establish strong relationships with reliable suppliers and set clear expectations for delivery times. Additionally, investing in advanced tracking technologies can help businesses monitor the movement of goods in real-time and identify any potential bottlenecks in the supply chain.</p>

Recommendations for Optimizing Last In First Out Practices

When it comes to optimizing Last In First Out practices in logistics, transport, and shipping, there are several recommendations that can help streamline operations and improve efficiency. One key strategy is to prioritize inventory based on demand forecasts and sales data. By ensuring that the most recent products are the first to be shipped out, you can minimize the risk of obsolescence and reduce holding costs.

Another crucial recommendation is to implement a robust tracking and monitoring system to accurately record the movement of goods in and out of the warehouse. This can help identify any bottlenecks or inefficiencies in the LIFO process and enable proactive steps to address them. Additionally, regular performance evaluations and feedback loops can aid in continuous improvement and optimization of Last In First Out practices.

Concluding Remarks

In conclusion, Last In First Out (LIFO) is a logistics strategy that can be effective in certain situations to streamline operations and optimize inventory management in the transport and shipping industry. By understanding the principles of LIFO and its potential impact on supply chain efficiency, businesses can make more informed decisions to enhance their overall performance. Whether it’s maximizing storage space or improving delivery times, incorporating LIFO into your logistics framework may just be the key to unlocking greater success in the world of transportation and shipping. Thank you for delving into the world of LIFO with us. Stay tuned for more insights and innovations in the ever-evolving landscape of the logistics industry.