In the intricate world of product development and manufacturing, every tweak, adjustment, and modification carries weight. Enter the Engineering Change Order (ECO) – the beacon of order amidst the chaos of innovation. But what about the logistics, the transport, the shipping of these crucial changes? In this article, we delve into the often overlooked but vitally important realm of ECO logistics, exploring the labyrinthine journey these alterations take from design desk to final destination. Join us on this enlightening expedition into the intricate world of ECO logistics – where change is not just an idea, but a meticulously orchestrated dance of precision and efficiency.

Key Considerations for Implementing Engineering Change Orders in Logistics

When it comes to implementing Engineering Change Orders (ECOs) in logistics, there are several key considerations that need to be taken into account to ensure a smooth and successful transition. One important factor to consider is the impact that the ECO will have on the transportation and shipping processes. It’s crucial to assess how the changes will affect the overall supply chain and whether adjustments need to be made to accommodate the new requirements.

Additionally, communication is key when implementing ECOs in logistics. Ensuring that all stakeholders are informed and aligned with the changes is essential for a successful transition. This includes coordinating with suppliers, carriers, and internal teams to minimize disruptions and optimize efficiency. By keeping lines of communication open and transparent, companies can navigate the challenges of implementing ECOs in logistics effectively.

Streamlining ECO Processes for Efficient Transport and Shipping Operations

One of the key challenges in the transport and shipping industry is the need to streamline Engineering Change Order (ECO) processes for more efficient operations. By optimizing the way ECOs are managed, companies can reduce delays, improve productivity, and enhance overall performance.

Efficient ECO processes help in minimizing disruptions in the supply chain, ensuring that products are transported and shipped on time. This, in turn, leads to cost savings and improved customer satisfaction. To achieve this, it is essential to leverage technology, automate repetitive tasks, and establish clear communication channels between all stakeholders involved in the transport and shipping operations.

Best Practices for Ensuring Smooth Collaboration Between Engineering and Logistics Teams

When it comes to ensuring a smooth collaboration between engineering and logistics teams, communication is key. By establishing clear channels of communication and setting up regular check-ins, both teams can stay informed and aligned on any changes or updates that may impact the transportation and shipping process. This can help to prevent any delays or disruptions in the supply chain.

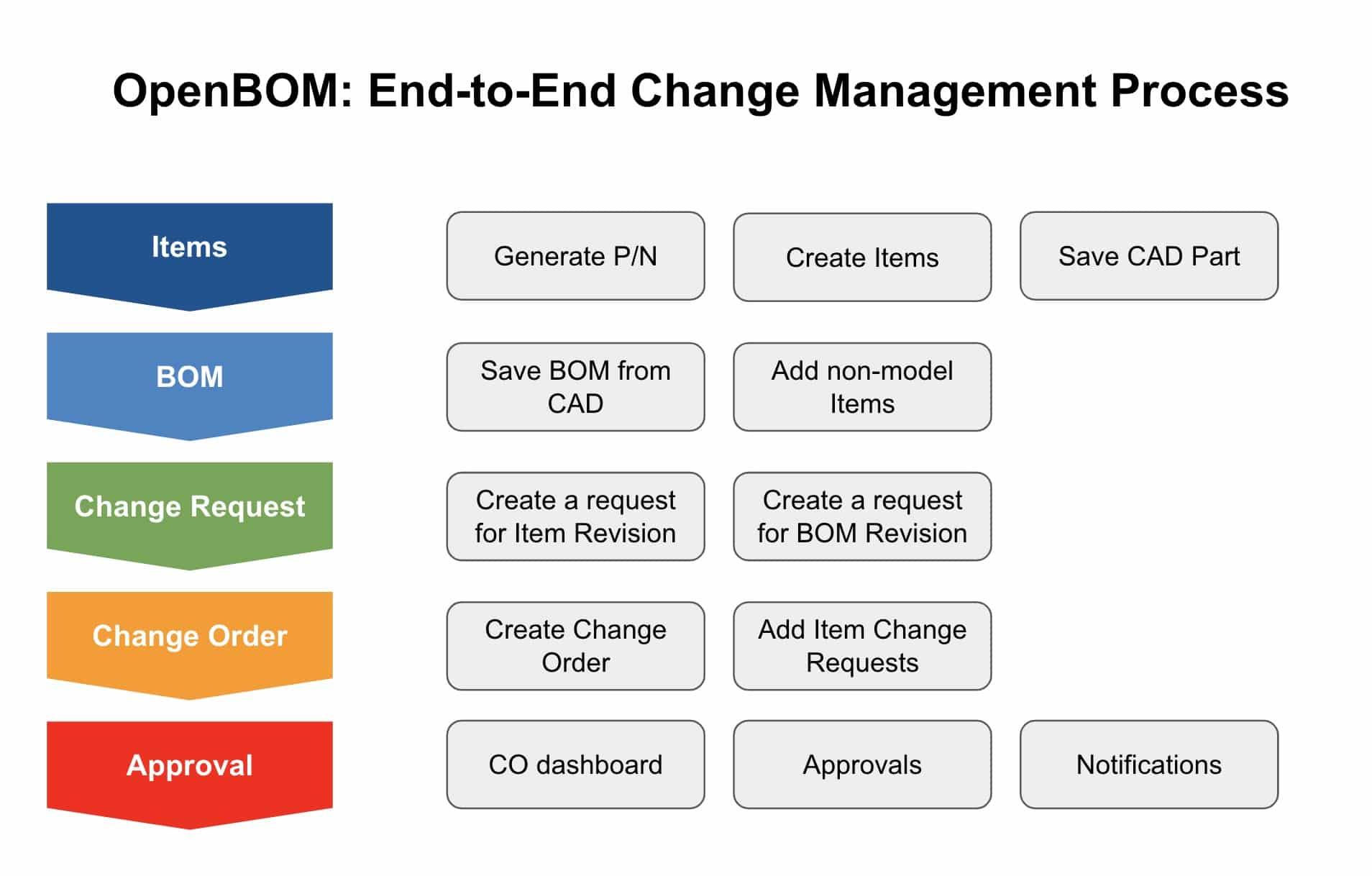

Another best practice is to establish a centralized system for tracking Engineering Change Orders (ECOs) that may impact logistics. By having a designated platform where both teams can access and update information regarding ECOs, it ensures that everyone is on the same page and can plan accordingly. Additionally, creating a cross-functional team that includes members from both engineering and logistics can help facilitate collaboration and problem-solving when unexpected issues arise.

Maximizing Cost Savings and Minimizing Delays Through Effective ECO Management

Effective management of Engineering Change Orders (ECO) is crucial for maximizing cost savings and minimizing delays in projects. By efficiently handling ECO logistics, transport, and shipping, businesses can streamline their operations and enhance overall project efficiency. Implementing a structured approach to ECO management can help companies avoid costly mistakes and ensure smooth project execution.

Utilizing robust ECO tracking systems and communication tools can improve collaboration among project stakeholders and facilitate timely decision-making. By clearly defining roles and responsibilities, establishing clear communication channels, and leveraging technology solutions, organizations can optimize their ECO processes and achieve greater project success. Embracing a proactive mindset towards ECO management can lead to improved project outcomes and enhanced customer satisfaction. Stay ahead of the curve by prioritizing effective ECO logistics and shipping strategies for your projects.

Final Thoughts

In conclusion, Engineering Change Orders are a critical aspect of the logistics, transport, and shipping industries. By carefully managing ECOs, companies can effectively implement necessary changes to products or processes while minimizing disruptions to operations. Whether it’s updating equipment, altering packaging, or improving transportation methods, ECOs play a crucial role in ensuring efficiency and quality in the supply chain. Stay tuned for more insights and best practices to streamline ECO logistics and drive positive change within your organization. Thank you for reading!