In the fast-paced world of logistics, transport, and shipping, maintaining a smooth and efficient supply chain is essential for success. But behind the scenes of seamless operations lies a hidden cost – maintenance. From troubleshooting hardware and software issues to performing routine upkeep, the maintenance costs associated with supply chain management processes can add up quickly. In this article, we will delve into the intricacies of these maintenance costs and explore the crucial role they play in keeping the wheels of the industry turning.

Understanding the Impact of Maintenance Costs on Supply Chain Management

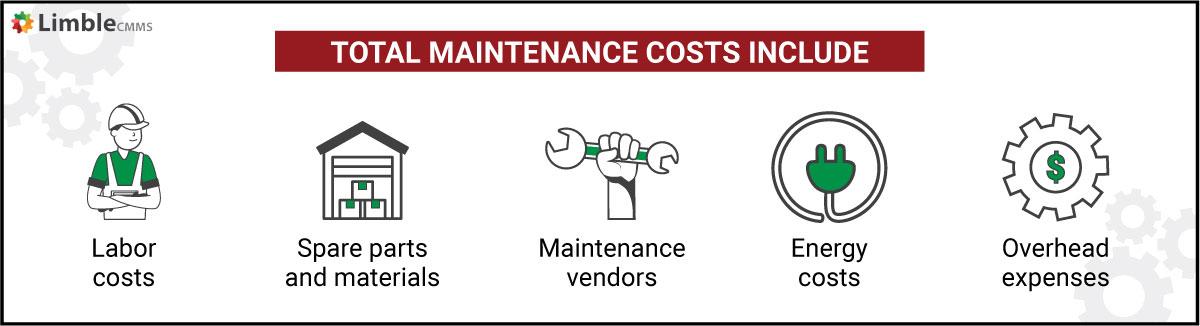

Maintenance costs play a crucial role in supply chain management as they directly impact the overall efficiency and effectiveness of the processes involved. These costs encompass expenses related to problem resolution, troubleshooting, repair, and routine maintenance of both hardware and software components within the supply chain management framework. From database administration systems to configuration control and release planning, every aspect of maintenance requires careful consideration to ensure smooth operations.

is essential for organizations to optimize their processes and maximize efficiency. By proactively managing and budgeting for maintenance expenses, companies can minimize downtime, improve reliability, and ultimately enhance the overall performance of their logistics, transport, and shipping operations. It is crucial for businesses to prioritize maintenance as a strategic investment rather than just an unavoidable cost, as it plays a pivotal role in ensuring the seamless functioning of the supply chain.

Key Factors Influencing Maintenance Costs in Logistics Operations

are crucial in ensuring the smooth functioning of supply chain management processes. One significant factor is the frequency of equipment breakdowns, which can lead to increased repair costs and downtime. Implementing preventive maintenance schedules can help reduce these breakdowns and minimize maintenance costs in the long run.

Additionally, the quality of equipment and technology being used in logistics operations plays a vital role in maintenance costs. Investing in high-quality hardware and software that are durable and reliable can help decrease the need for frequent repairs and replacements. Proper training for staff members on equipment usage and maintenance can also contribute to cost savings by reducing the likelihood of user errors leading to costly repairs. By prioritizing equipment reliability and maintenance best practices, logistics companies can effectively manage maintenance costs and optimize their supply chain operations.

Strategies for Reducing Maintenance Costs in Shipping and Transport Processes

One effective strategy for reducing maintenance costs in shipping and transport processes is to implement regular preventative maintenance schedules for all equipment and vehicles. By conducting routine inspections and addressing any potential issues before they become major problems, companies can avoid costly repairs and downtime. This proactive approach can help extend the lifespan of equipment and minimize the need for expensive repairs in the long run.

Another cost-saving strategy is to invest in modern technology and software solutions that can streamline maintenance processes and help identify potential issues before they escalate. Utilizing predictive maintenance tools and software can help companies analyze data and predict when maintenance is needed, allowing for more efficient scheduling and resource allocation. By embracing digital solutions, companies can improve operational efficiency, reduce downtime, and ultimately lower maintenance costs.

| Preventative Maintenance Benefits | Digital Maintenance Solutions |

|---|---|

| Extend equipment lifespan | Streamline maintenance processes |

| Minimize downtime | Identify potential issues early |

| Reduce costly repairs | Improve operational efficiency |

Closing Remarks

In conclusion, understanding and managing maintenance costs in supply chain management processes is crucial for ensuring the smooth operation of logistics, transport, and shipping activities. By effectively addressing problems, troubleshooting issues, and conducting routine maintenance on hardware and software systems, businesses can minimize disruptions and optimize efficiency. From database administration to release planning, every aspect of maintenance plays a key role in streamlining operations and reducing overall costs. By staying proactive and investing in proper maintenance strategies, organizations can pave the way for success in the competitive world of logistics and shipping.