In the fast-paced world of logistics, transport, and shipping, the concept of just-in-time has revolutionized the way businesses operate. In this article, we will explore the importance of eliminating any activities that do not add value to the final product or service in the eyes of the consumer. Join us as we delve into the intricacies of streamlining processes to ensure maximum efficiency and customer satisfaction.

Value-Adding Activities in Just-in-Time Operations

In just in time operations, the focus is on eliminating any activities that do not directly contribute to adding value to the end product or service. This includes streamlining logistics processes such as transport and shipping to ensure that products reach consumers in the most efficient and cost-effective way possible.

By prioritizing value-adding activities in logistics, companies can reduce waste, improve customer satisfaction, and increase profitability. This approach involves optimizing supply chain management, minimizing inventory levels, and collaborating closely with suppliers to meet consumer demand in a timely manner.

Maximizing Efficiency in Logistics Operations

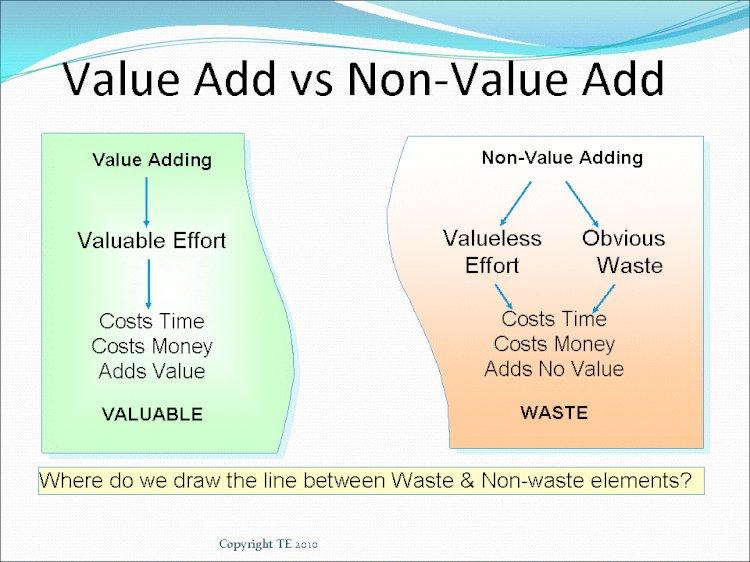

One key aspect of is the concept of just in time (JIT) manufacturing. In JIT, any activity that does not add value to the good or service in the eyes of the consumer is eliminated. This means that unnecessary steps in the logistics process are identified and eliminated, streamlining operations and reducing waste.

Implementing JIT in logistics can lead to significant cost savings and improved customer satisfaction. By focusing on delivering goods to customers exactly when they are needed, businesses can reduce inventory carrying costs, minimize storage space requirements, and improve overall supply chain efficiency. In addition, JIT helps to identify bottlenecks in the logistics process, allowing for better resource allocation and more effective use of transportation and shipping services.

Strategies for Eliminating Non-Value Adding Activities in Shipping Operations

In just in time shipping operations, it is crucial to eliminate any activities that do not add value to the end product or service. Non-value adding activities not only waste time and resources but also increase costs and reduce efficiency. By identifying and eliminating these unnecessary tasks, companies can streamline their shipping operations and improve overall performance.

One strategy for eliminating non-value adding activities is to conduct a thorough analysis of the entire shipping process. This involves identifying each step in the process and evaluating whether it directly contributes to the final product or service. Any activities that do not add value should be either optimized or eliminated altogether. Additionally, implementing lean principles, such as reducing transportation waste and improving workflow efficiency, can help companies achieve a more streamlined and cost-effective shipping operation.

The Way Forward

As we have delved into the world of just-in-time manufacturing and the critical importance of eliminating non-value added activities, we have gained a deeper understanding of the intricate web that is logistics, transport, and shipping. By streamlining processes and focusing on enhancing value for the consumer, businesses can truly thrive in today’s competitive marketplace. So, let us continue to explore the possibilities that exist within this realm, finding innovative ways to optimize efficiency and deliver exceptional goods and services to those who matter most – the consumers.Embark on this journey with a renewed perspective and a commitment to excellence. The future of logistics, transport, and shipping awaits, ready to be shaped by those who dare to push the boundaries of what is possible.