In the fast-paced world of logistics, meeting customer demand while maintaining efficiency is a constant challenge. The practice of Build to Stock logistics has emerged as a strategic approach to streamline operations and ensure products are readily available when needed. From transport to shipping, this article dives into the intricacies of Build to Stock logistics and how it is shaping the future of supply chain management.

Optimizing Supply Chain Efficiency through Build to Stock Strategy

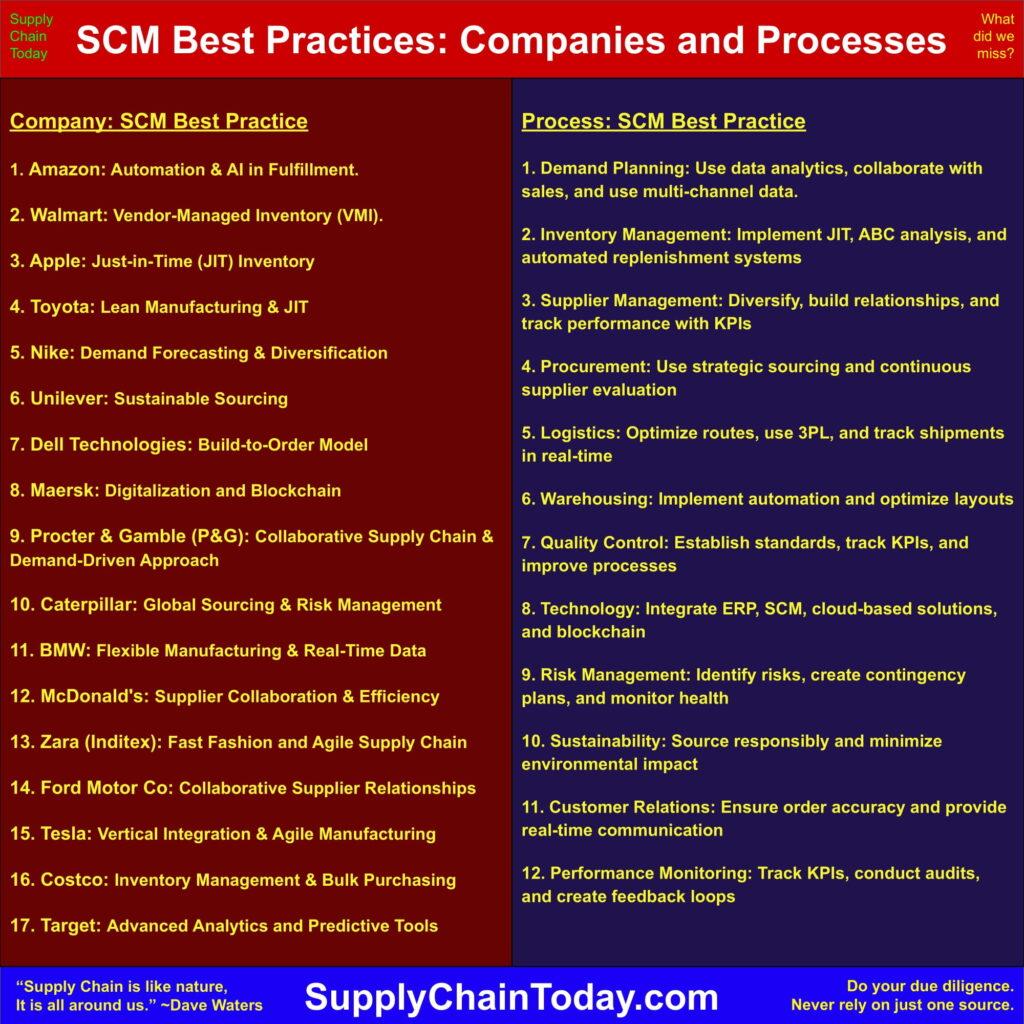

One key aspect of optimizing supply chain efficiency is the implementation of a build to stock strategy. By producing goods based on anticipated demand rather than waiting for specific orders, companies can reduce lead times, minimize stockouts, and improve overall customer satisfaction. This approach involves forecasting consumer preferences, market trends, and historical sales data to efficiently produce and stock inventory.

With a build to stock strategy in place, companies can streamline their logistics, transport, and shipping processes. By having the right products readily available in warehouses, manufacturers can quickly fulfill orders, reduce shipping times, and lower overall transportation costs. This not only improves operational efficiency but also helps in meeting customer demand promptly, ultimately enhancing the overall supply chain performance and competitiveness in the market.

Streamlining Logistics Operations for Build to Stock Manufacturing

Efficient logistics operations are crucial for build to stock manufacturing processes. By streamlining transportation and shipping, companies can minimize delays, reduce costs, and improve overall customer satisfaction. Utilizing advanced logistics software and automation can help optimize inventory management, warehouse operations, and delivery processes.

Key strategies for improving logistics operations in build to stock manufacturing include:

- Implementing Just-In-Time (JIT) delivery systems

- Utilizing route optimization software for efficient transportation

- Collaborating closely with suppliers to ensure timely delivery of materials

Key Considerations for Shipping Build to Stock Products

When shipping build to stock products, there are several key considerations that need to be taken into account to ensure a smooth and efficient process. One important factor to consider is the packaging of the products. It is crucial to use durable and secure packaging to protect the products during transit and minimize the risk of damage. Additionally, labeling the packages with clear and accurate information such as product codes, descriptions, and quantities is essential for efficient handling and tracking.

Another key consideration is choosing the right shipping method based on factors such as the size and weight of the products, delivery timelines, and cost efficiency. Whether using freight carriers, parcel services, or a combination of both, it is important to carefully evaluate the options available and select the most suitable shipping solution for your build to stock products. Proper documentation and communication with shipping partners are also vital to ensure smooth coordination and timely delivery of the products to their destination.

Maximizing Transport Networks for Build to Stock Delivery

When it comes to build to stock delivery, maximizing transport networks is crucial for efficient logistics and shipping operations. By optimizing routes, selecting the most cost-effective carriers, and leveraging technology solutions, companies can streamline their supply chain processes and enhance customer satisfaction.

One effective strategy for maximizing transport networks is to implement a hub-and-spoke system, where goods are consolidated at distribution centers before being shipped to various locations. This approach helps reduce transportation costs, minimize lead times, and improve inventory management. Additionally, utilizing real-time tracking devices and predictive analytics can provide valuable insights into the status of shipments, allowing companies to proactively address any issues that may arise. With a well-designed transport network in place, build to stock delivery can be executed with precision and efficiency, meeting the demands of today’s fast-paced marketplace.

In Summary

In conclusion, Build to Stock logistics plays a crucial role in ensuring products are delivered efficiently and on time. By effectively managing transport and shipping processes, companies can streamline operations, reduce costs, and ultimately improve customer satisfaction. With the right strategies in place, businesses can build a strong foundation for success in the competitive world of supply chain management. Thank you for reading, and we hope this article has provided valuable insight into the importance of Build to Stock logistics. Stay tuned for more informative content on this topic in the future.