In the intricate web of logistics, transport, and shipping, identifying the root cause of issues is paramount to effectively maintaining the smooth flow of goods and materials. Root cause analysis serves as a strategic tool, delving deep into the underlying issues that can disrupt the seamless operation of supply chains. In this article, we will explore the importance of root cause analysis in the realm of logistics, transport, and shipping, and how it can help companies navigate the complex world of global commerce with precision and efficiency. Join us as we unravel the mysteries of root cause analysis and its vital role in ensuring the seamless transfer of goods across the world.

Identifying the Root Causes of Delays in Logistics Operations

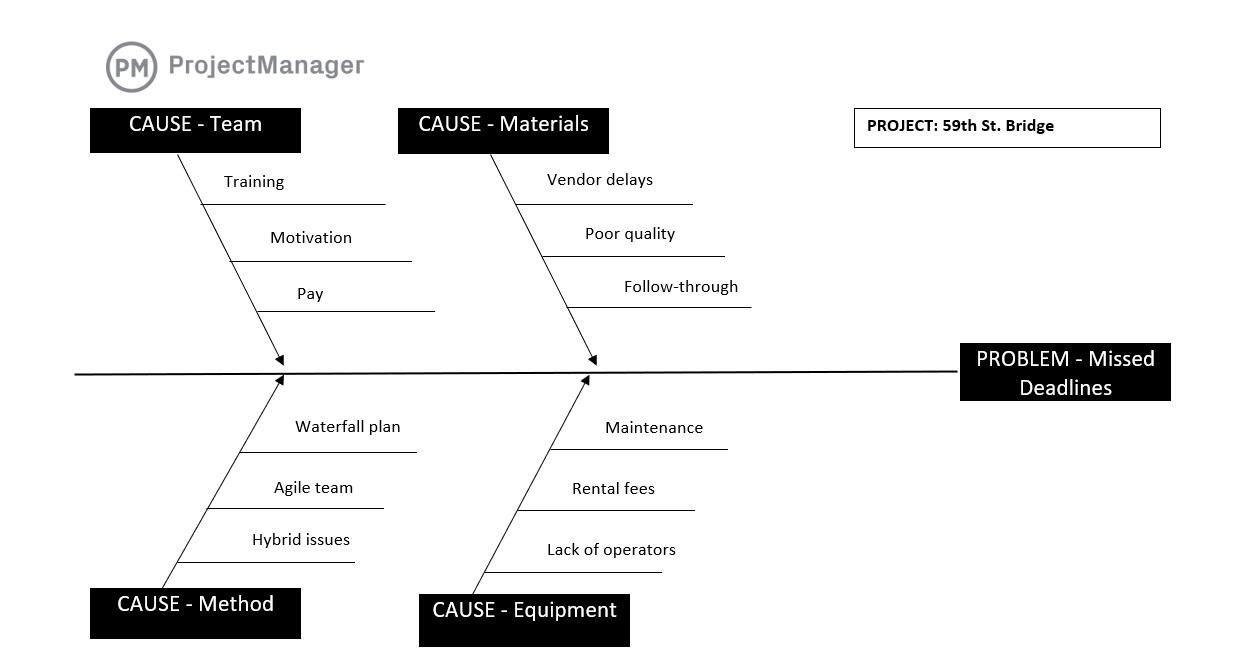

is crucial for improving efficiency and productivity in the supply chain. By conducting a thorough root cause analysis, companies can pinpoint the underlying issues that are causing delays and develop effective strategies to address them. Common root causes of delays in logistics operations include:

- Poor communication: Miscommunication between different departments or with external partners can lead to delays in the transportation and shipping process.

- Inefficient processes: Outdated or inefficient processes can slow down operations and cause delays in delivery times.

- Lack of visibility: Limited visibility into inventory levels, shipment status, or other key data points can result in delays and disruptions in logistics operations.

By identifying and addressing these root causes, companies can streamline their operations, reduce delays, and ultimately improve customer satisfaction. Implementing technology solutions, improving communication channels, and optimizing processes are just a few ways companies can mitigate delays in logistics operations and drive greater efficiency in their supply chain.

The Importance of Root Cause Analysis in Improving Transport Efficiency

Root cause analysis is a crucial tool in the world of logistics, transport, and shipping. By identifying the underlying causes of inefficiencies, delays, and errors, businesses can make targeted improvements to their operations. This methodical approach allows companies to address issues at their source, rather than just treating the symptoms.

Through root cause analysis, companies can uncover hidden problems that may be hindering their transport efficiency. By digging deep to find the true origins of issues, organizations can implement lasting solutions that result in smoother operations, reduced costs, and improved customer satisfaction. This proactive approach is key to staying competitive in the fast-paced world of transportation and logistics.

Analyzing Shipping Errors and Finding Sustainable Solutions

Shipping errors can be a nightmare for companies, leading to delays, extra costs, and unhappy customers. To effectively address these issues, it’s crucial to conduct a thorough root cause analysis. By digging deep into the underlying reasons for these errors, businesses can uncover the true source of the problem and implement sustainable solutions to prevent them from happening again.

One common shipping error is incorrect labeling, which can result in packages being sent to the wrong destination. This type of mistake can occur due to human error, outdated systems, or lack of training. By identifying the root cause of labeling errors, companies can implement measures such as employee training programs, barcode scanning technology, and automated labeling systems to ensure accurate and efficient shipping processes.

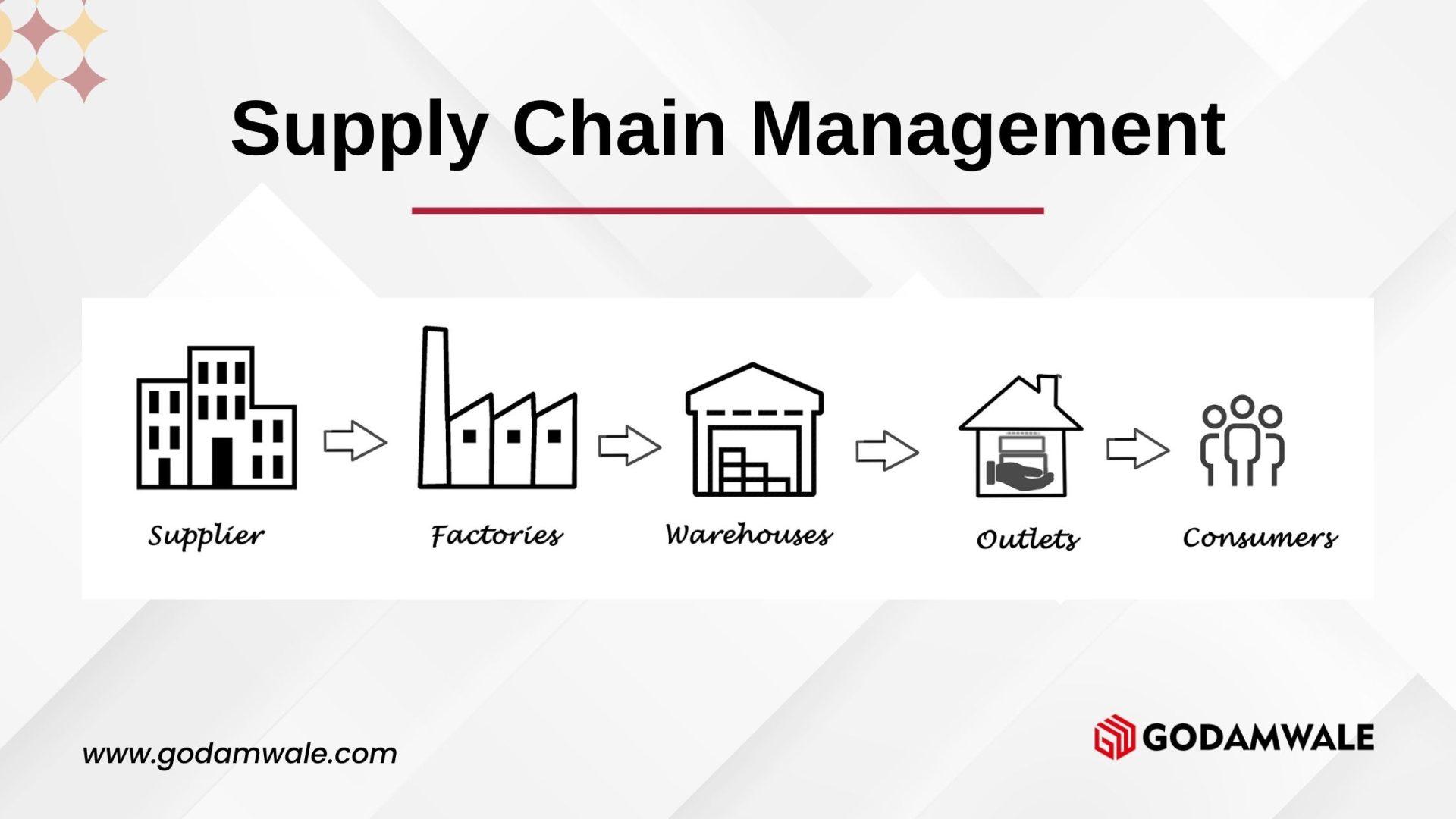

Enhancing Supply Chain Performance Through Root Cause Analysis

Root cause analysis is a critical tool in the realm of logistics, transport, and shipping. By delving deep into the underlying factors contributing to inefficiencies or disruptions in the supply chain, organizations can pinpoint the root causes of issues and implement targeted solutions for sustainable improvement.

- Identifying specific areas for improvement

- Reducing costs and waste

- Enhancing overall operational efficiency

- Improving customer satisfaction

Through a systematic approach to root cause analysis, businesses can streamline processes, optimize resource utilization, and foster a culture of continuous improvement. By addressing the core issues at the heart of supply chain challenges, companies can drive meaningful change and achieve tangible results in their logistics operations.

Insights and Conclusions

In conclusion, Root Cause Analysis plays a critical role in improving the efficiency and effectiveness of logistics, transport, and shipping operations. By identifying and addressing the underlying issues that lead to disruptions and delays, companies can streamline their processes, reduce costs, and enhance customer satisfaction. By implementing RCA methodologies, organizations can optimize their supply chain management and drive overall performance. As the saying goes, “prevention is better than cure,” and Root Cause Analysis is the key to preventing problems before they occur in the fast-paced world of logistics. Through a proactive approach to problem-solving, businesses can stay ahead of the curve and deliver reliable, timely, and cost-effective solutions to their customers. So, let’s dive deep into the root causes and pave the way for a smoother, more efficient future in the world of logistics, transport, and shipping.