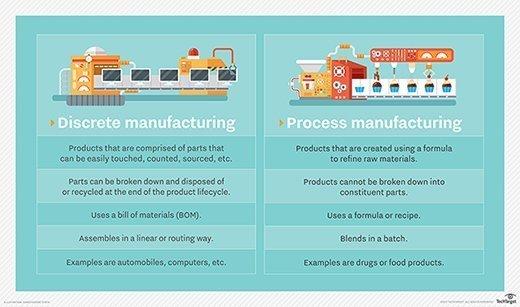

In the intricate world of manufacturing, the swift and seamless movement of goods is paramount. From the moment a product is made to the time it reaches the hands of the consumer, a complex dance of logistics, transportation, and shipping takes place. In this article, we delve into the world of discrete manufacturing logistics, where every step is carefully orchestrated to ensure that products make their way from the factory floor to their final destination with precision and efficiency. Join us as we explore the inner workings of this essential process and uncover the key players and strategies that drive it forward.

– Streamlining Transportation Routes for Efficient Delivery

When it comes to discrete manufacturing, efficient transportation routes are essential for smooth operations and timely deliveries. By streamlining transportation routes, companies can optimize their shipping processes and reduce costs. One way to achieve this is by utilizing advanced logistics systems that can analyze data and suggest the most efficient routes based on factors such as traffic conditions, fuel prices, and delivery deadlines.

Another important aspect of streamlining transportation routes is proper coordination between different modes of transport. By integrating shipping, trucking, and rail services, companies can create a seamless delivery network that minimizes delays and maximizes efficiency. Using GPS tracking systems and real-time information sharing, businesses can ensure that shipments are always on track and reach their destinations on time. By adopting these strategies, companies can improve their overall logistics operations and provide better service to their customers.

– Implementing Just-In-Time Delivery Strategies for Reduced Inventory Costs

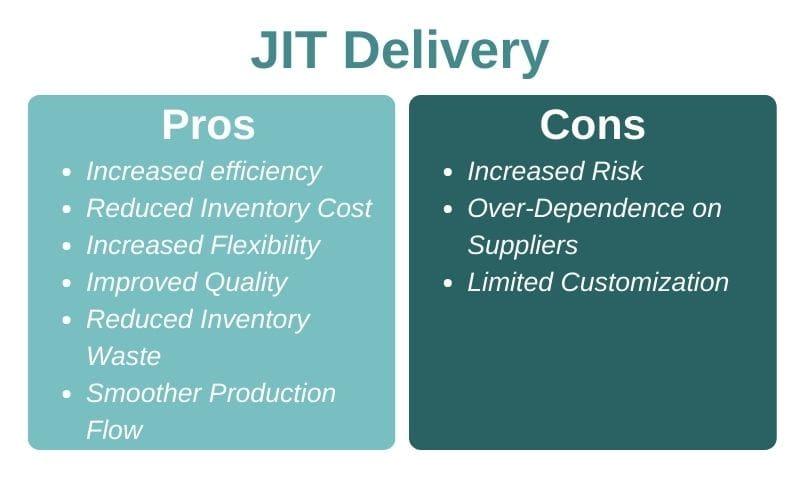

In today’s fast-paced world, the demand for efficient supply chain management in discrete manufacturing industries is more critical than ever. Implementing Just-In-Time Delivery strategies can significantly reduce inventory costs while increasing operational efficiency. By ensuring that materials and components are delivered to the production line exactly when they are needed, companies can minimize excess inventory and storage costs.

Utilizing real-time data and advanced scheduling systems, manufacturers can streamline their production processes and improve overall productivity. By strategically partnering with reliable suppliers and optimizing transportation routes, companies can further enhance their logistics operations and achieve cost savings. Embracing Just-In-Time Delivery strategies is not just a trend, but a necessity for discrete manufacturing businesses looking to stay competitive in today’s market.

– Optimizing Shipping Processes Through Automation and Technology Integration

In today’s fast-paced world of discrete manufacturing, logistics, transport, and shipping play a crucial role in ensuring that products reach customers efficiently and on time. With the constant need to streamline operations and reduce costs, optimizing shipping processes through automation and technology integration has become essential for businesses to stay competitive in the market.

By embracing automation and integrating the latest technologies into their shipping processes, companies can greatly improve efficiency, accuracy, and speed in fulfilling orders. Utilizing barcode scanning systems, RFID tags, and automated sorting can help minimize errors, reduce manual labor, and enhance overall supply chain visibility. Through the use of transport management systems (TMS) and warehouse management systems (WMS), businesses can better track shipments, optimize routes, and manage inventory more effectively. The adoption of real-time tracking and predictive analytics also enables companies to proactively address potential shipping delays and improve customer satisfaction.

– Enhancing Supply Chain Visibility for Improved Decision Making & Customer Satisfaction

One crucial aspect of enhancing supply chain visibility in discrete manufacturing is through efficient logistics, transport, and shipping processes. By implementing advanced technologies and strategies, manufacturers can track their inventory, monitor shipments, and analyze data to make informed decisions that improve overall efficiency and customer satisfaction.

With real-time visibility into every step of the supply chain, manufacturers can proactively address any issues that may arise, minimize delays, and optimize resources. This ultimately leads to faster delivery times, reduced costs, and increased customer loyalty. By leveraging data analytics and automation tools, manufacturers can achieve a competitive edge in the market and deliver high-quality products consistently.

The Conclusion

In conclusion, the world of discrete manufacturing logistics, transport, and shipping is a complex and intricate web of systems and processes that ensure products move seamlessly from production to the hands of consumers. It requires careful planning, precision execution, and constant innovation to meet the demands of today’s fast-paced world. As technology continues to evolve and supply chains become more globalized, the importance of efficient logistics and shipping in discrete manufacturing cannot be understated. By staying ahead of trends, embracing new technologies, and prioritizing collaboration with partners, companies can navigate the ever-changing landscape of manufacturing logistics with ease. Remember, success in discrete manufacturing is not just about making the product, but about getting it to the right place at the right time. Let’s keep moving forward together.