In the fast-paced world of logistics, every second counts. From airplanes soaring through the sky to trucks navigating highways, efficiency is key to a successful delivery. One often overlooked factor in the world of transportation is aerodynamic drag. This seemingly minor force can have a major impact on fuel consumption, shipping costs, and overall logistics. In this article, we will explore the intricate relationship between aerodynamic drag and the world of transport and shipping, and how it plays a crucial role in ensuring goods reach their destination swiftly and cost-effectively.

Understanding the Impact of Aerodynamic Drag on Shipping Efficiency

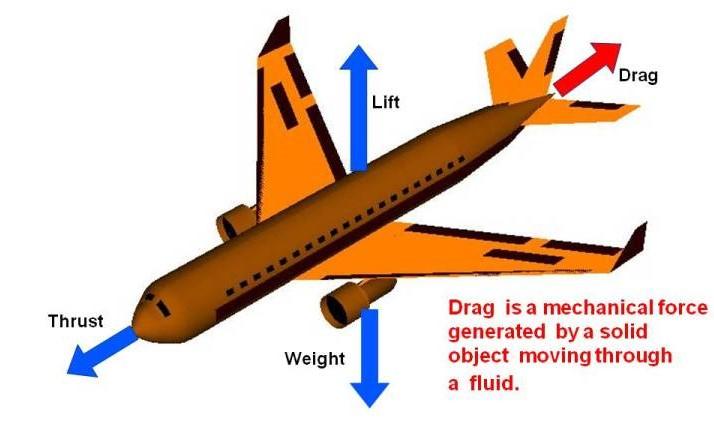

When it comes to shipping efficiency, understanding the impact of aerodynamic drag is crucial. Aerodynamic drag is the force that opposes the motion of an object through the air, and in the world of logistics and transport, it plays a significant role in determining fuel consumption and overall efficiency. By reducing aerodynamic drag, shipping companies can save money on fuel costs and reduce their carbon footprint.

There are several factors that contribute to aerodynamic drag, including the shape and size of the shipping vessel, wind resistance, and the speed at which the vessel is traveling. By optimizing the design of shipping containers and vessels, companies can minimize aerodynamic drag and improve fuel efficiency. Additionally, implementing technologies such as air deflectors and streamlined shapes can further reduce drag and enhance overall shipping performance.

Implementing Innovative Solutions to Reduce Aerodynamic Drag in Logistics

One innovative solution to reduce aerodynamic drag in logistics is the implementation of streamlined vehicle designs. By utilizing advanced aerodynamics principles, such as reducing frontal area and smoothing out vehicle surfaces, companies can significantly decrease drag forces. This can lead to improved fuel efficiency and reduced emissions, making transportation more environmentally friendly.

Another creative approach is the use of aerodynamic add-ons, such as side skirts and roof fairings, to optimize airflow around trucks and trailers. These additions can help minimize air resistance, ultimately lowering fuel consumption. Additionally, incorporating technologies like trailer tail devices can further enhance aerodynamic performance, maximizing fuel savings and enhancing overall logistics efficiency.

Maximizing Fuel Efficiency through Aerodynamic Design in Transportation

When it comes to maximizing fuel efficiency in transportation, aerodynamic design plays a crucial role in reducing drag and improving overall performance. By optimizing the shape and design of vehicles, whether it be trucks, trains, or ships, companies can significantly decrease the amount of energy needed to move their goods from one place to another.

One way to achieve this is by incorporating sleek and streamlined designs that minimize air resistance. This can include features such as:

- Tapered Front Ends: reducing the frontal area exposed to air flow

- Smooth Surfaces: reducing turbulent air flow over the vehicle

- Optimized Trailer Tails: reducing drag at the rear of trailers

Best Practices for Minimizing Aerodynamic Drag in Shipping Operations

When it comes to shipping operations, minimizing aerodynamic drag is essential for improving fuel efficiency and reducing costs. By implementing best practices, companies can optimize their logistics and transport processes to enhance overall performance. One key strategy is to streamline the shape of containers and trailers to reduce wind resistance. This can be achieved by using aerodynamic fairings and skirts, as well as ensuring that cargo is loaded efficiently to minimize air turbulence.

Another effective way to minimize aerodynamic drag in shipping operations is to maintain proper tire pressure. Underinflated tires can increase rolling resistance, which in turn creates more drag. By regularly checking and adjusting tire pressure, companies can improve fuel efficiency and reduce wear and tear on their vehicles. Additionally, optimizing route planning and scheduling to minimize stops and idle time can help to further reduce aerodynamic drag and improve overall transport efficiency.

Insights and Conclusions

In conclusion, understanding aerodynamic drag is crucial in the world of logistics, transport, and shipping. By optimizing the design of vehicles, reducing unnecessary bulky loads, and utilizing innovative technologies, we can minimize the impact of aerodynamic drag and enhance efficiency in transportation networks. As we continue to strive for sustainability and improved performance, keeping aerodynamics in mind will be key in shaping the future of transportation. So, let us navigate the winds of change and soar towards a more streamlined and eco-friendly tomorrow.