In the fast-paced world of e-commerce and distribution, efficient batch picking is the unsung hero behind seamless logistics, transport, and shipping operations. As warehouses buzz with activity and orders pour in, the art of batch picking plays a crucial role in maximizing productivity and minimizing errors. Join us as we delve into the world of batch picking and uncover its impact on the intricate dance of supply chain management.

Boosting Efficiency through Batch Picking

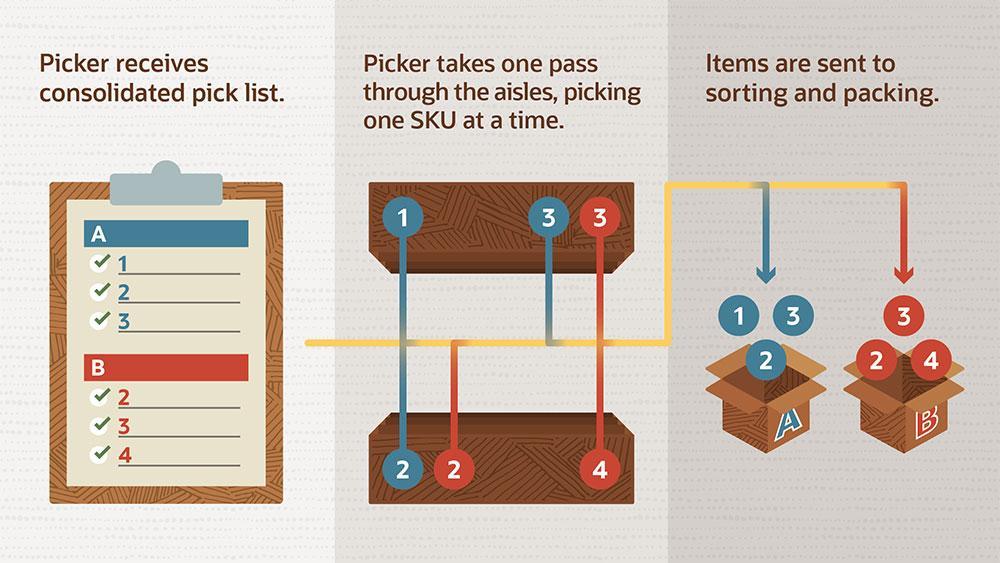

Batch picking is a crucial strategy in warehouse management that can significantly boost efficiency and productivity. By grouping multiple orders together and picking them simultaneously, companies can reduce the time and resources needed to fulfill customer orders. This method not only streamlines the picking process but also minimizes travel time within the warehouse, ultimately leading to faster order fulfillment and reduced labor costs.

With batch picking, warehouse operators can optimize their picking routes, pick multiple orders in a single pass, and maximize their overall picking efficiency. This results in fewer empty trips, reduced congestion in the warehouse aisles, and improved order accuracy. By implementing batch picking processes, companies can enhance their logistics operations, improve shipment accuracy, and ultimately provide better service to their customers.

Streamlining Operations with Advanced Logistics Solutions

Implementing batch picking in your logistics operations can significantly streamline your processes and improve efficiency. By grouping multiple orders together and picking them simultaneously, you can reduce travel time and increase productivity. This advanced logistics solution allows you to fulfill orders quicker and more accurately, ultimately leading to higher customer satisfaction.

With batch picking, you can optimize your warehouse layout to maximize space utilization and minimize errors. By organizing items by pick frequency and proximity to each other, you can further streamline operations and reduce fulfillment times. This innovative approach to logistics can revolutionize your shipping processes and help you stay ahead of the competition in today’s fast-paced industry.

Maximizing Cost Savings in Transport and Shipping Processes

When it comes to , batch picking is an essential strategy that can streamline operations and reduce expenses. By grouping orders together and picking them in batches, companies can optimize their warehouse efficiency while minimizing labor costs. This method not only saves time but also reduces the number of trips required to fulfill orders, ultimately lowering transportation expenses.

Implementing batch picking in logistics can lead to significant cost savings for businesses. By consolidating orders and picking them in bulk, companies can take advantage of economies of scale and negotiate better shipping rates with carriers. Additionally, batch picking reduces the likelihood of errors and improves order accuracy, ultimately enhancing customer satisfaction. With the right technology and processes in place, organizations can achieve a more efficient and cost-effective transport and shipping process.

Implementing Best Practices for Successful Batch Picking Operations

One key aspect of successful batch picking operations is to optimize the layout of your warehouse to minimize travel time and increase efficiency. Consider grouping items together based on frequency of order, size, weight, or other relevant factors. This can help reduce the distance traveled by your pickers and improve overall productivity. Additionally, utilizing technology such as barcode scanners and pick-to-light systems can further streamline the picking process and reduce errors.

Another best practice is to establish clear picking guidelines and standard operating procedures to ensure consistency and accuracy in your operations. Train your staff thoroughly on these procedures and regularly review and update them as needed. Monitoring key performance indicators such as picking accuracy and speed can also help identify areas for improvement and drive operational excellence. By implementing these best practices, you can enhance the efficiency and effectiveness of your batch picking operations, ultimately leading to better customer satisfaction and increased profitability.

The Conclusion

In conclusion, batch picking is a crucial strategy in the world of logistics, transport, and shipping. By efficiently consolidating multiple orders into one picking process, businesses can save time, reduce labor costs, and increase overall productivity. However, it is important for companies to carefully analyze their operations and implement the right technology and processes to ensure success. With the right approach, batch picking can streamline operations and improve customer satisfaction. Stay tuned for more insights and tips on optimizing your supply chain management strategies. Thank you for reading!