In the fast-paced world of logistics, ensuring the right amount of goods are available at all times is crucial for businesses to thrive. Enter buffer stock logistics – a strategic approach that keeps supply chains running smoothly, transport systems efficient, and shipping processes seamless. Join us as we delve into the world of buffer stock logistics and uncover its impact on the world of transportation and shipping.

Ensuring Smooth Operations with Buffer Stock Management

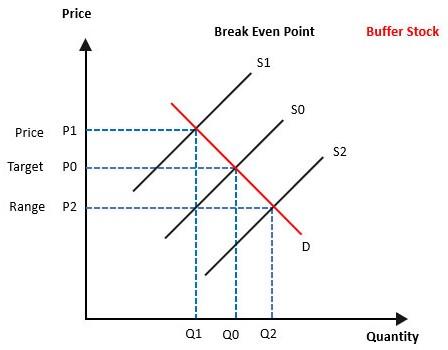

Managing buffer stock effectively is crucial for businesses operating in the logistics, transport, and shipping industries. By maintaining a buffer stock, companies can ensure smooth operations and mitigate risks associated with fluctuations in demand, supply chain disruptions, and other unforeseen events. Buffer stock management involves carefully balancing inventory levels to meet customer demand while avoiding excess stock that can tie up working capital.

Key benefits of implementing buffer stock management include:

- Improved customer satisfaction: By having buffer stock in place, companies can fulfill orders quickly and efficiently, leading to higher customer satisfaction.

- Enhanced supply chain flexibility: Buffer stock allows businesses to adapt to changes in demand or supply chain disruptions without causing delays or shortages.

- Reduced stockouts: By maintaining a buffer stock, companies can minimize the risk of stockouts and ensure continuity in operations.

Streamlining Transport Processes for Efficient Logistics

One key strategy in is implementing buffer stock management. Buffer stock involves keeping a supply of extra inventory on hand to prevent stockouts and delays in the transport and shipping process. By maintaining buffer stock, companies can ensure that they have enough products readily available to meet unexpected spikes in demand or delays in transportation.

Additionally, utilizing technology such as automated inventory systems and real-time tracking tools can help in effectively managing buffer stock levels. These tools can provide valuable data insights on inventory levels, demand trends, and shipping timelines, enabling logistics teams to make data-driven decisions to optimize their transport processes. By leveraging technology and implementing buffer stock strategies, companies can enhance their logistics operations and improve overall efficiency in their supply chain management.

Maximizing Efficiency in Shipping with Proper Buffer Stock Planning

Proper buffer stock planning is essential for maximizing efficiency in shipping operations. By strategically managing buffer stock levels, companies can ensure uninterrupted supply chains and minimize the risks associated with delays and disruptions. Buffer stock serves as a safety net that allows businesses to handle unexpected fluctuations in demand or supply, reducing the likelihood of stockouts and improving customer satisfaction.

Key Benefits of Buffer Stock Planning for Shipping:

- Reduces lead times and improves order fulfillment

- Enhances flexibility in responding to changing market conditions

- Helps optimize inventory levels and reduce holding costs

- Minimizes the impact of production disruptions and transportation delays

Key Recommendations for Implementing Buffer Stock Strategies in Logistics and Transportation

When implementing buffer stock strategies in logistics and transportation, it is crucial to carefully consider the following key recommendations:

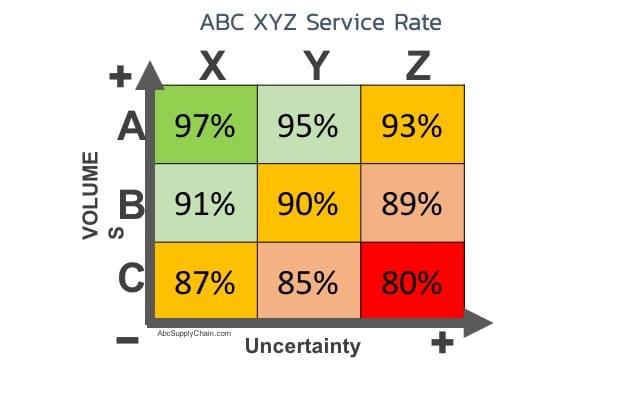

- Utilize data-driven forecasting: Implement advanced forecasting tools to accurately predict demand fluctuations and adjust buffer stock levels accordingly.

- Establish strong relationships with suppliers: Collaborate closely with suppliers to ensure a continuous and reliable supply chain, minimizing the risk of stockouts.

- Optimize inventory management: Implement efficient inventory control systems to minimize carrying costs while ensuring buffer stock levels meet demand fluctuations.

Additionally, consider incorporating safety stock buffers, implementing Just-In-Time (JIT) principles, and regularly reviewing and adjusting buffer stock levels to adapt to changing market conditions. By following these recommendations, organizations can effectively manage uncertainties and minimize disruptions in logistics and transportation operations.

Closing Remarks

In conclusion, buffer stock logistics play a crucial role in ensuring that goods are available when and where they are needed. By using strategic storage facilities and supply chain management techniques, businesses can minimize the risk of stockouts and surpluses, ultimately optimizing their transportation and shipping operations. Whether it’s storing excess inventory to meet unexpected demand or buffering against disruptions in the supply chain, a well-implemented buffer stock system can help businesses navigate the unpredictable nature of the market. So next time you think about logistics, remember the power of buffer stock in keeping the wheels of transport and shipping turning smoothly.