In the fast-paced world of production and distribution, a well-oiled supply chain is essential to ensuring products reach their destination efficiently and on time. Among the many methods of logistics, one strategy that has gained traction in recent years is Build to Inventory. This approach focuses on creating and storing goods in anticipation of customer demand, streamlining the transportation and shipping process along the way. Join us as we delve into the intricate world of Build to Inventory logistics, exploring how businesses are revolutionizing their supply chain operations to meet the demands of a modern marketplace.

– Streamlining Build to Inventory Processes for Increased Efficiency

When it comes to streamlining build to inventory processes for increased efficiency, it is essential to focus on optimizing every step of the logistics, transport, and shipping operations. By carefully planning and coordinating these key elements, businesses can reduce lead times, minimize stockpile costs, and improve overall productivity.

One effective way to enhance efficiency in the build to inventory process is to implement advanced tracking systems for real-time monitoring of shipments. This technology allows companies to identify potential bottlenecks, proactively address delays, and ensure that products are delivered to the right place at the right time. Additionally, creating a seamless communication network between suppliers, manufacturers, and distributors can help streamline operations and improve coordination across the entire supply chain.

– Optimizing Logistics Strategies for Seamless Transportation

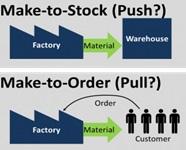

Build to inventory is a logistics approach that focuses on producing goods based on forecasted demand rather than actual orders. This strategy allows companies to have products ready to ship immediately, reducing lead times and streamlining the transportation process. By optimizing inventory levels and production schedules, companies can ensure seamless transportation from the manufacturing plant to distribution centers and ultimately to customers.

When implementing a build to inventory strategy, it is crucial to have a well-planned logistics infrastructure in place. This includes efficient warehouse management systems, streamlined transportation routes, and effective shipping processes. By leveraging technology such as RFID tracking and automated inventory management systems, companies can improve visibility and control over their supply chain. Additionally, partnering with reliable transportation providers and implementing real-time tracking tools can help ensure on-time deliveries and minimize disruptions in the transportation network.

– Maximizing Shipping Efforts for On-Time Deliveries

When it comes to maximizing shipping efforts for on-time deliveries, one effective strategy is implementing a Build to Inventory (BTI) approach. By utilizing BTI logistics, companies can streamline their production processes, reduce lead times, and ensure that products are readily available for shipping at any given time. This proactive method involves forecasting demand, building up inventory levels, and aligning shipping and delivery schedules to meet customer expectations.

With BTI logistics, companies can take advantage of economies of scale by producing goods in larger quantities, which can lead to cost savings on manufacturing and shipping expenses. Additionally, having a well-stocked inventory can help mitigate supply chain disruptions and delays, allowing for faster order processing and fulfillment. By optimizing their logistics, transport, and shipping operations, businesses can improve efficiency, minimize freight costs, and ultimately enhance customer satisfaction with timely deliveries.

– Implementing Best Practices to Enhance Build to Inventory Operations

Implementing best practices in build to inventory operations is crucial for streamlining logistics, transport, and shipping processes. By optimizing these key areas, businesses can improve efficiency, reduce costs, and enhance customer satisfaction.

Some best practices to consider include:

- Utilizing advanced inventory management software to track and manage inventory levels accurately

- Implementing lean manufacturing principles to minimize waste and optimize production processes

- Collaborating closely with suppliers to ensure timely delivery of materials

- Regularly reviewing and updating supply chain strategies to adapt to changing market conditions

Future Outlook

In conclusion, the Build to Inventory logistics approach offers a strategic advantage for businesses looking to streamline their transportation and shipping processes. By creating and maintaining a ready-made inventory, companies can respond quickly to customer demands and reduce lead times. With careful planning and efficient logistics management, Build to Inventory can help businesses stay ahead of the competition in today’s fast-paced market. Embracing this approach can lead to increased efficiency, cost savings, and ultimately, improved customer satisfaction. So, why wait? Start implementing Build to Inventory logistics in your business today and see the difference it can make. Happy shipping!