In the ever-evolving world of logistics and supply chain management, Continuous Replenishment Planning (CRP) has emerged as a crucial strategy for staying ahead in the competitive marketplace. From efficient transportation to seamless shipping processes, CRP plays a pivotal role in optimizing the flow of goods from manufacturers to consumers. Join us as we explore the ins and outs of CRP in the realm of logistics, transport, and shipping, and discover how this innovative approach is revolutionizing the way businesses manage their inventory and meet customer demands.

Enhancing Supply Chain Efficiency through Continuous Replenishment Planning

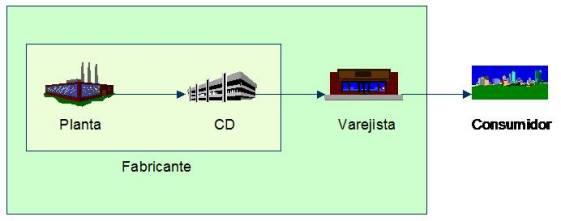

Continuous Replenishment Planning (CRP) is a strategic approach to supply chain management that focuses on maintaining optimal inventory levels by continuously monitoring and replenishing stock as needed. By implementing CRP in logistics operations, businesses can streamline their supply chain processes, reduce costs, and improve overall efficiency. This innovative approach ensures that products are always available when needed, minimizing stockouts and excess inventory.

One of the key benefits of Continuous Replenishment Planning is its ability to enhance collaboration between suppliers, manufacturers, and retailers. By sharing real-time data and insights, stakeholders can make more informed decisions and respond quickly to changes in demand. This proactive approach to inventory management not only improves customer satisfaction but also helps to reduce lead times, increase fill rates, and drive profitability. With CRP, businesses can achieve a leaner and more agile supply chain that is well-equipped to adapt to evolving market conditions and customer demands.

Innovative Strategies for Optimizing Logistics Operations with CRP

When it comes to optimizing logistics operations, Continuous Replenishment Planning (CRP) offers innovative strategies that can revolutionize the way businesses manage their supply chains. By implementing CRP, organizations can streamline their inventory management processes, reduce costs, and improve overall efficiency. One key benefit of CRP is the ability to automatically replenish inventory levels based on real-time data, ensuring that products are always in stock and ready to be shipped to customers.

With CRP, businesses can also enhance their forecasting capabilities by analyzing historical data and trends to predict future demand more accurately. This can help companies avoid stockouts and overstock situations, leading to better inventory management and cost savings. By leveraging CRP technology, organizations can take their logistics operations to the next level and stay ahead of the competition in today’s fast-paced business environment.

Maximizing Shipping Performance with Continuous Replenishment Planning

Continuous Replenishment Planning (CRP) is a powerful strategy that can greatly improve shipping performance for businesses. By continuously monitoring inventory levels and automatically generating orders to replenish stock, companies can ensure that products are always available for shipping, reducing the risk of delays or stockouts. This proactive approach to inventory management not only streamlines the shipping process but also helps optimize warehouse space and minimize holding costs.

With CRP, companies can establish more efficient shipping schedules, reduce lead times, and increase on-time deliveries. By automating the replenishment process, businesses can react quickly to changes in demand and avoid costly disruptions in their supply chain. Additionally, CRP can help businesses lower their transportation costs by optimizing shipping routes and consolidating shipments. By maximizing shipping performance through Continuous Replenishment Planning, companies can improve customer satisfaction and gain a competitive edge in today’s fast-paced market.

Best Practices for Implementing CRP in Transport Management

In order to effectively implement Continuous Replenishment Planning (CRP) in transport management, several best practices should be followed. Firstly, it is crucial to establish a strong collaboration between the logistics and shipping teams to ensure seamless communication and coordination. Clear communication channels and regular meetings can help streamline the CRP process and avoid any bottlenecks or disruptions in the supply chain.

Another key practice is to leverage technology and automate as many processes as possible. By integrating a reliable CRP software solution, businesses can optimize their transport management operations, reduce manual errors, and improve overall efficiency. Additionally, regular monitoring and analysis of key performance indicators (KPIs) can provide valuable insights into the effectiveness of the CRP strategy and help identify areas for improvement.

In Summary

In conclusion, Continuous Replenishment Planning (CRP) is a vital strategy in the world of logistics, transport, and shipping. By implementing a continuous flow of goods, businesses can optimize their inventory levels, reduce costs, and improve customer satisfaction. With the ever-changing landscape of global supply chains, CRP offers a dynamic approach to meeting consumer demands in real-time. As the industry continues to evolve, integrating CRP into your operations can set you ahead of the competition and drive success in the future. Stay tuned for more insights and tips on how to navigate the complex world of logistics with Continuous Replenishment Planning. Thank you for reading!