In the fast-paced world of commerce, the efficiency of logistics and shipping operations can make or break a business. Continuous Replenishment Logistics is a cutting-edge approach that aims to streamline the transportation and shipping process, ensuring that goods are constantly moving and restocking shelves in a timely manner. In this article, we will delve into the world of Continuous Replenishment Logistics, exploring its benefits, challenges, and impact on the modern supply chain. Join us as we unravel the complexities of this innovative approach to transportation and shipping.

The Importance of Continuous Replenishment in Logistics

Continuous replenishment plays a crucial role in the efficiency of logistics operations. By maintaining a steady flow of stock and supplies, companies can minimize stockouts, reduce excess inventory, and improve overall supply chain performance. This proactive approach to inventory management helps to ensure that products are always available when needed, leading to increased customer satisfaction and loyalty.

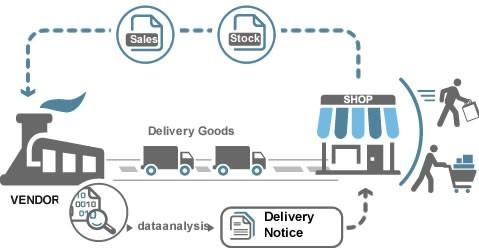

Implementing continuous replenishment strategies requires effective communication and collaboration between suppliers, manufacturers, and retailers. By sharing real-time data and demand forecasts, stakeholders can streamline ordering processes, minimize lead times, and optimize transportation and shipping schedules. This seamless coordination not only improves inventory turnover rates but also reduces costs associated with storage and holding inventory. Ultimately, continuous replenishment in logistics is essential for maintaining a competitive edge in today’s fast-paced business environment.

Optimizing Transport Efficiency for Continuous Replenishment

In the world of continuous replenishment logistics, optimizing transport efficiency is essential for ensuring smooth operations. By fine-tuning transportation processes, companies can minimize costs and maximize productivity. One key aspect of optimizing transport efficiency is route planning, which involves mapping out the most efficient routes for deliveries to minimize travel time and fuel consumption.

Another crucial factor in optimizing transport efficiency is load optimization. By strategically organizing and consolidating shipments, companies can ensure that trucks are filled to capacity, reducing the number of trips needed to replenish inventory. Additionally, real-time tracking technology can be utilized to monitor shipments and make adjustments on the fly, optimizing transport efficiency and ensuring timely deliveries.

Strategies for Streamlining Shipping in Continuous Replenishment

One key strategy for streamlining shipping in continuous replenishment is to optimize routes and transportation modes. By analyzing shipping data and trends, companies can identify the most efficient routes and modes of transportation for their products. This can help reduce shipping costs, improve delivery times, and minimize environmental impact. Utilizing a transportation management system (TMS) can also help automate and optimize the shipping process, leading to greater efficiency.

Another strategy is to establish strong partnerships with reliable carriers and suppliers. By working closely with trusted partners, companies can ensure smoother logistics operations and better communication throughout the shipping process. Collaborating with carriers and suppliers that have a strong track record of performance and reliability can help prevent shipping delays and disruptions. Implementing vendor managed inventory (VMI) programs can also help improve inventory management and streamline the replenishment process.

Maximizing Inventory Management through Continuous Replenishment Logistics

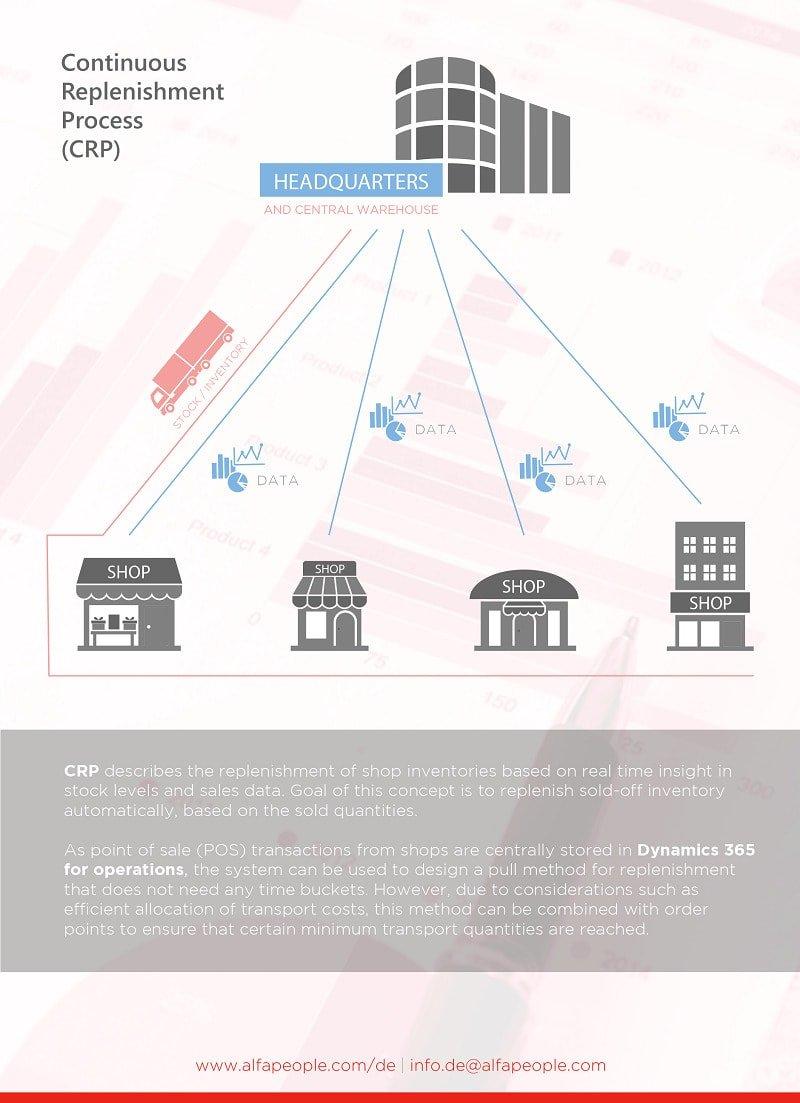

Continuous replenishment logistics is a strategic approach that aims to minimize inventory costs and maximize customer satisfaction by automatically refilling stock based on real-time data. By implementing this system, businesses can ensure that products are always available when needed, reducing the risk of stockouts and overstocking. This method allows for a more efficient supply chain, leading to cost savings and improved overall performance.

One key benefit of continuous replenishment logistics is the ability to streamline the shipping process. With automated stock replenishment, businesses can better predict demand and plan shipments accordingly. This leads to reduced lead times, lower transportation costs, and improved overall efficiency. By optimizing transportation and shipping through continuous replenishment logistics, businesses can ensure that products reach customers in a timely manner while minimizing unnecessary costs.

In Summary

As we navigate the complex world of continuous replenishment logistics, transport, and shipping, one thing remains clear: the key to success lies in seamless coordination and efficient communication. By embracing the latest technologies and innovative strategies, we can meet the evolving demands of the modern supply chain with ease. So, let’s continue to adapt, innovate, and collaborate, as we pave the way for a more efficient and sustainable future in the world of logistics. Together, we can ensure that goods are delivered on time, every time, and keep the world moving forward.