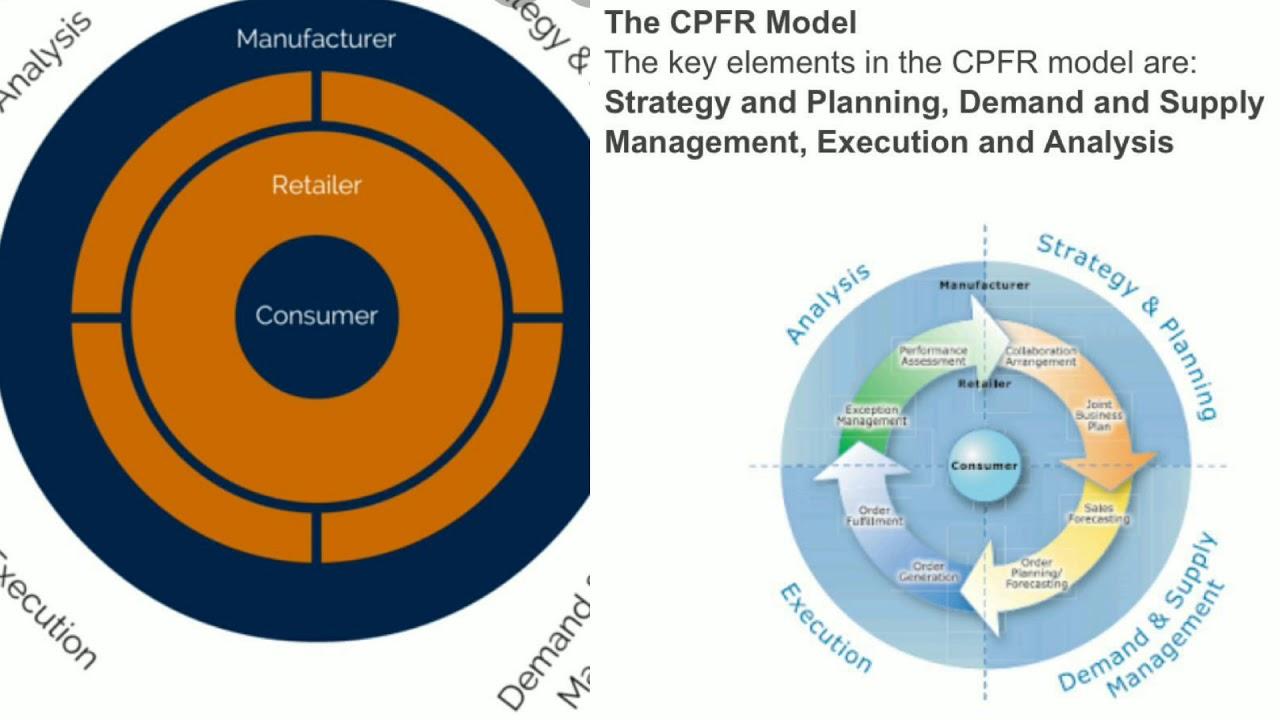

In today’s fast-paced world of global commerce, effective supply chain management is key to staying ahead of the competition. Collaborative Planning, Forecasting, and Replenishment (CPFR) has emerged as a game-changing strategy in the logistics, transport, and shipping industries. By harnessing the power of real-time data, advanced technology, and strong partnerships, CPFR is revolutionizing the way businesses streamline their operations and drive profitability. Join us as we explore the dynamic world of CPFR logistics and discover how this innovative approach is reshaping the future of supply chain management.

Benefits of Implementing CPFR in Logistics Operations

Implementing CPFR in logistics operations offers a wide range of benefits that can streamline the transport and shipping processes. Collaborative Planning, Forecasting, and Replenishment improve communication and visibility throughout the supply chain, resulting in more efficient operations and cost savings. By sharing data and forecasts with partners, companies can better anticipate demand and adjust inventory levels accordingly.

Furthermore, CPFR allows for better coordination between suppliers, manufacturers, and retailers, leading to improved inventory management and reduced stockouts. This collaborative approach fosters stronger relationships between trading partners, leading to increased trust and improved overall performance. Ultimately, implementing CPFR in logistics operations can lead to increased customer satisfaction and a competitive edge in the market.

Maximizing Efficiency through Integrated Transport Solutions

Integrated transport solutions are key to maximizing efficiency in the supply chain. By combining various modes of transportation, from trucks to trains to ships, companies can streamline their logistics processes and reduce costs. With CPFR (Collaborative Planning, Forecasting, and Replenishment) at the core of this strategy, businesses can work closely with their transport partners to optimize routes, schedules, and inventory levels.

Imagine a scenario where real-time data feeds into a centralized system, allowing all parties involved to make informed decisions on the fly. By leveraging advanced technologies like GPS tracking, RFID tags, and automated scheduling tools, companies can ensure that goods are delivered just-in-time, every time. This level of coordination not only improves operational efficiency but also enhances customer satisfaction, leading to repeat business and sustainable growth in the long run.

Strategies for Streamlining Shipping Processes

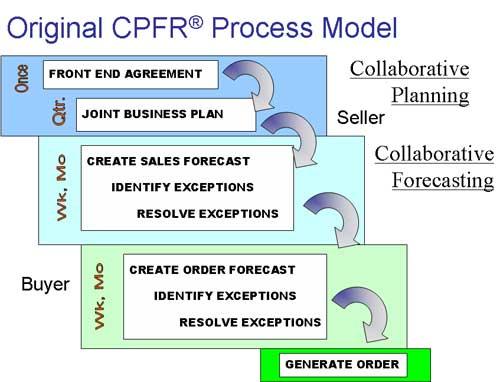

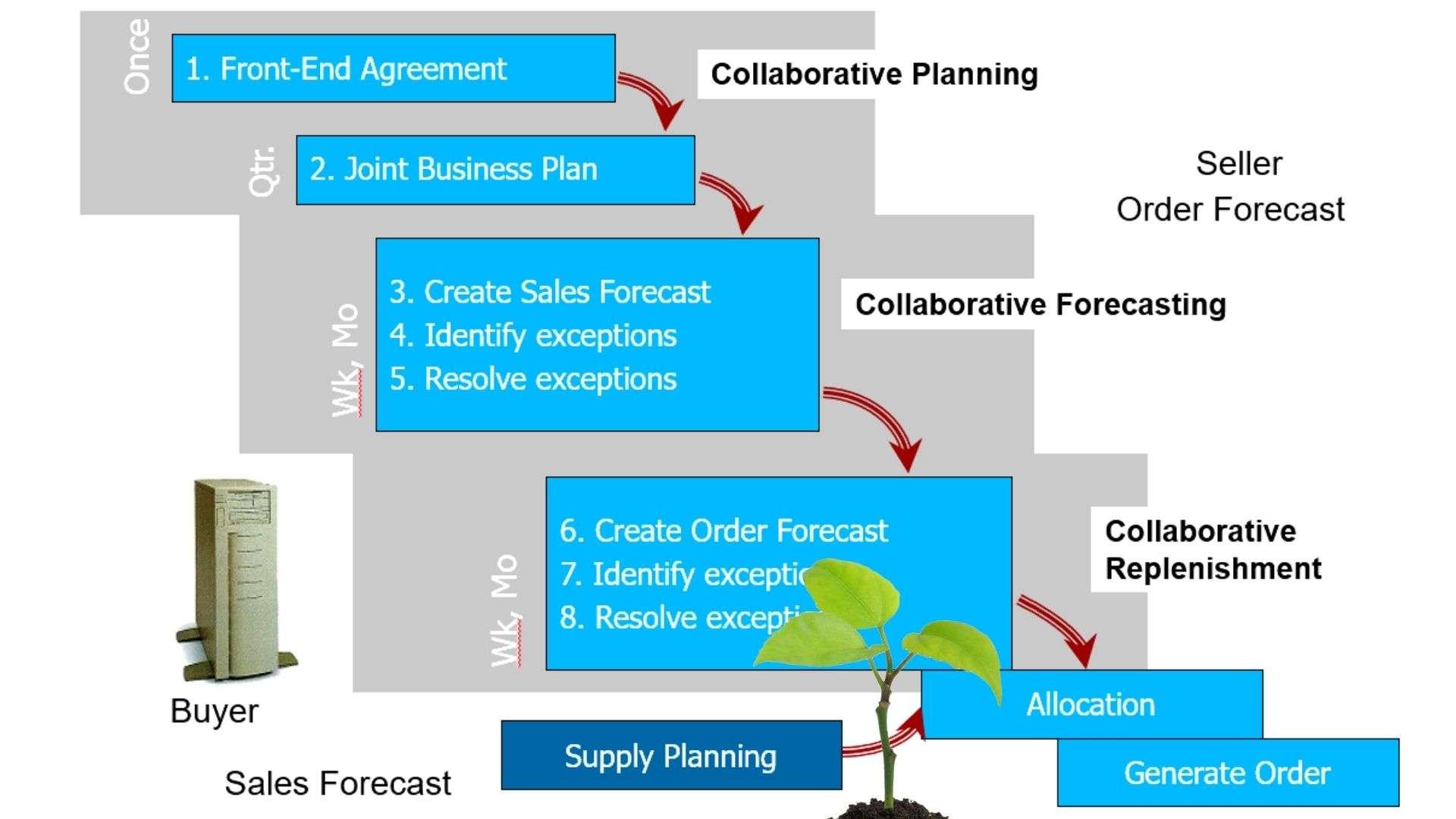

In the world of logistics and shipping, efficiency is key. Streamlining shipping processes can help businesses save time and money while ensuring customer satisfaction. One effective strategy for optimizing shipping operations is to implement a Collaborative Planning, Forecasting, and Replenishment (CPFR) approach. By working closely with suppliers and customers to create accurate forecasts and develop collaborative plans, companies can reduce lead times, minimize stockouts, and improve overall supply chain performance.

Another essential strategy for streamlining shipping processes is to invest in advanced transportation management systems. These systems can help businesses automate and optimize their freight management, carrier selection, routing, and tracking processes. By leveraging the latest technology and data analytics, companies can improve shipment visibility, reduce transportation costs, and enhance delivery performance. Embracing digital tools and solutions can revolutionize the way businesses manage their shipping operations, leading to greater efficiency and competitiveness in today’s fast-paced global marketplace.

Key Takeaways for Successful CPFR Implementation in Supply Chain Operations

Implementing Collaborative Planning, Forecasting, and Replenishment (CPFR) in supply chain operations can be a game-changer for businesses looking to improve efficiency and visibility in their logistics, transport, and shipping processes. Here are some key takeaways for successful CPFR implementation:

- Build Strong Partnerships: Establishing strong relationships with your suppliers, distributors, and retailers is crucial for effective CPFR. Communication and collaboration are key to ensuring that everyone is aligned on goals and objectives.

- Utilize Technology: Investing in the right technology and software solutions can streamline CPFR processes and improve accuracy in forecasting and planning. Automated systems can help track inventory levels, monitor demand, and analyze data to make better-informed decisions.

Wrapping Up

In conclusion, CPFR (Collaborative Planning, Forecasting, and Replenishment) is a powerful tool that can revolutionize the way logistics, transport, and shipping industries operate. By fostering collaboration and communication between different partners in the supply chain, CPFR has the potential to streamline processes, reduce costs, and improve efficiency. As technology continues to advance, it is important for businesses to embrace innovative solutions like CPFR to stay competitive in today’s rapidly evolving global marketplace. Let’s embrace the power of collaboration and drive change in the logistics industry together.