In an ever-evolving world where efficiency and precision are paramount, the design of experiments (DOE) plays a crucial role in optimizing logistics, transport, and shipping processes. From determining the most cost-effective shipping routes to minimizing delivery times, DOE offers a systematic approach to solving complex problems and improving overall performance. Join us as we delve into the world of DOE logistics and discover how this innovative methodology is revolutionizing the way we think about transportation and shipping.

Planning the Experiment Design for Efficient Logistics Operations

Design of Experiments (DOE) Logistics – Transport – Shipping

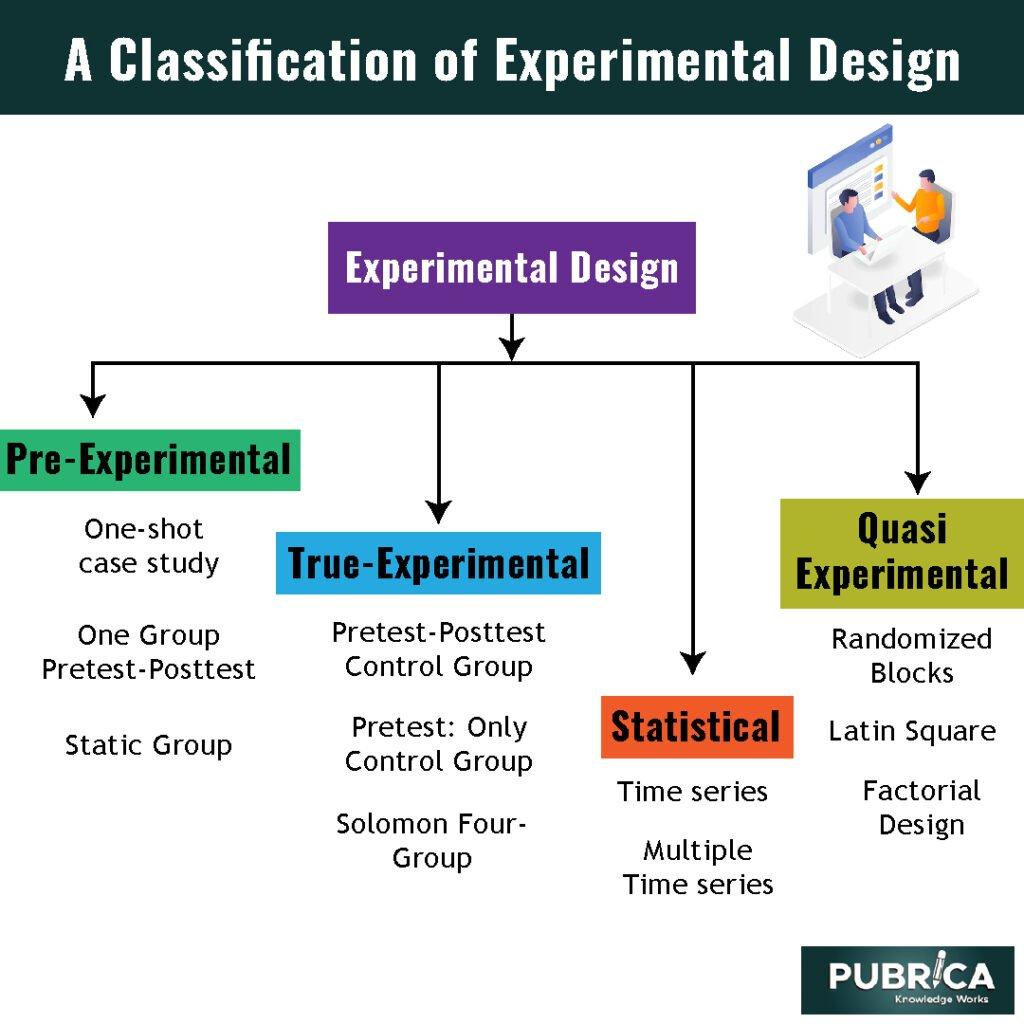

When , it is crucial to consider all aspects of the supply chain to ensure smooth and cost-effective transportation of goods. By using Design of Experiments (DOE) methodology, logistics managers can identify key variables that impact efficiency and strategically test different combinations to find the optimal solution. This approach allows for systematic evaluation of factors such as transportation modes, routing strategies, warehouse locations, and delivery schedules.

Utilizing DOE in logistics operations can lead to significant improvements in overall supply chain performance. By designing experiments that test various scenarios and collect data on key performance indicators, companies can make informed decisions to streamline their processes and reduce costs. Through careful planning and analysis, logistics managers can identify areas for improvement, implement changes, and ultimately enhance their operations to meet the demands of today’s fast-paced market.

Analyzing the Key Components of Transport in Design of Experiments

Transport is a critical component in the design of experiments, impacting the logistics and shipping processes involved. Ensuring the efficient movement of materials and equipment is essential for the success of any experiment. Proper planning and coordination of transport logistics can help streamline the overall experimental process and minimize delays.

Key considerations in the transport component of a design of experiments include:

- Transportation mode selection: Choosing the most suitable mode of transport, whether by air, sea, road, or rail, based on the specific requirements of the experiment.

- Shipping regulations compliance: Adhering to all relevant shipping regulations to ensure the safe and legal transport of materials.

- Route optimization: Planning the most efficient transport routes to minimize time and costs associated with shipping.

Strategies for Optimizing Shipping Processes in Design of Experiments

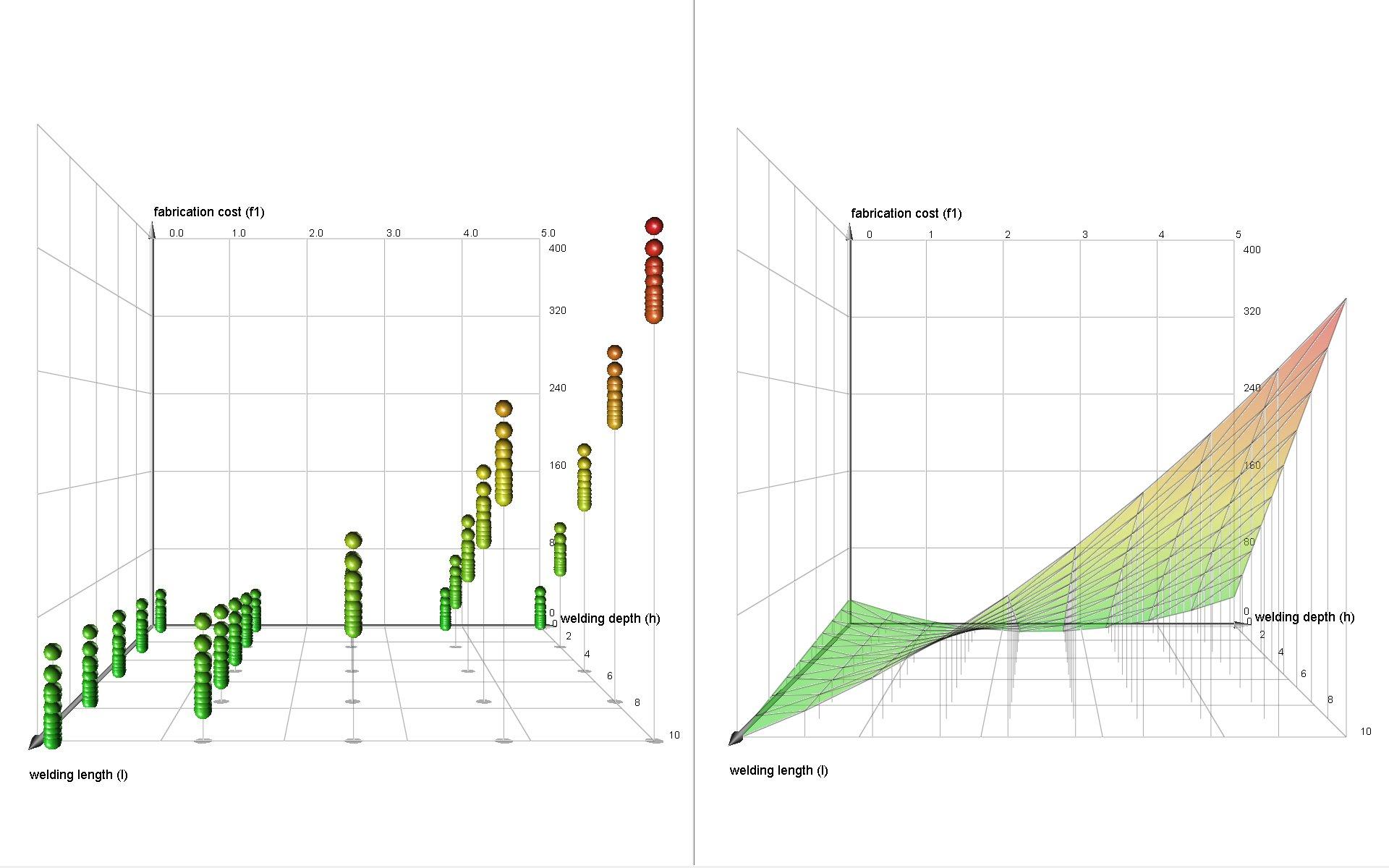

When it comes to optimizing shipping processes in the design of experiments, there are several strategies that can be employed to ensure efficiency and cost-effectiveness. Utilizing a systematic approach such as Design of Experiments (DOE) can help identify the most effective variables to focus on when optimizing shipping logistics. By carefully designing experiments and analyzing data, businesses can uncover valuable insights to streamline their shipping processes.

One key strategy is to prioritize collaboration between different departments involved in the shipping process, such as procurement, operations, and logistics. By working together and sharing data, teams can identify bottlenecks and inefficiencies in the shipping process and develop solutions to address them. Additionally, businesses can leverage technology such as transportation management systems to automate and optimize shipping routes, reduce transit times, and minimize shipping costs. By implementing these strategies, businesses can improve their shipping processes and enhance overall operational efficiency.

Implementing DOE Principles to Enhance Supply Chain Management

When it comes to optimizing supply chain management, implementing Design of Experiments (DOE) principles can bring about significant improvements in logistics, transport, and shipping operations. By using a systematic approach to testing various factors and their interactions, businesses can identify the most efficient and cost-effective strategies for managing their supply chains.

Through the use of DOE techniques, companies can experiment with different variables such as transportation routes, packaging methods, and inventory levels to determine the optimal combination that minimizes costs and maximizes efficiency. By analyzing the results of these experiments, organizations can make data-driven decisions that lead to streamlined supply chain processes and improved overall performance.

Concluding Remarks

In conclusion, Design of Experiments (DOE) plays a crucial role in the logistics, transport, and shipping industries. By carefully planning and executing experiments, companies can optimize their processes, reduce costs, and improve overall efficiency. With DOE, businesses can unlock valuable insights that can drive innovation and success in the rapidly evolving world of logistics. Embracing the power of experimentation in logistics is key to staying competitive and thriving in today’s dynamic market. Let us continue to explore new ways to improve and streamline our operations, making the most of the opportunities that DOE presents. Thank you for joining us on this journey through the fascinating world of DOE logistics.