In today’s fast-paced and interconnected world, businesses are constantly seeking innovative ways to streamline their supply chain and gain a competitive edge. One such strategy that has been gaining traction in the realm of logistics, transport, and shipping is Early Supplier Involvement (ESI). By engaging suppliers early in the design and development process, companies stand to benefit from improved collaboration, enhanced product quality, and more efficient delivery. In this article, we will explore the benefits and challenges of ESI in the context of logistics, transport, and shipping, and examine how this approach is revolutionizing the way businesses approach their supply chain management.

Understanding Early Supplier Involvement (ESI) in the Logistics Process

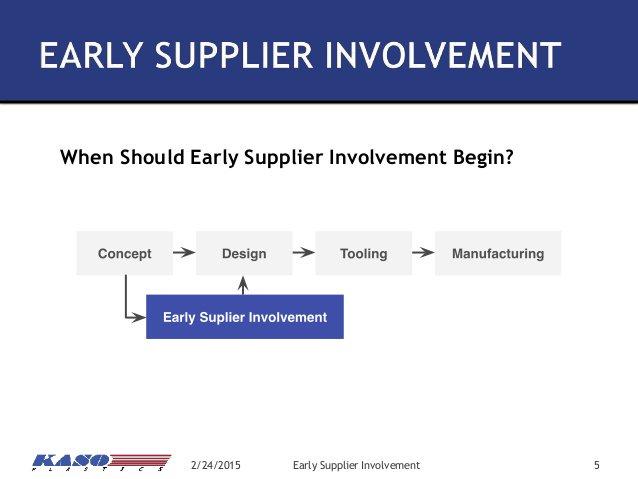

Early Supplier Involvement (ESI) is a strategic approach that involves engaging suppliers early in the product development process to maximize their potential value contribution, streamline logistics operations, and enhance overall supply chain efficiency. By involving suppliers from the initial stages of product design, companies can leverage their expertise, resources, and capabilities to optimize the delivery of goods and services. ESI in the logistics process focuses on building collaborative relationships with suppliers to drive innovation, reduce costs, and improve delivery performance.

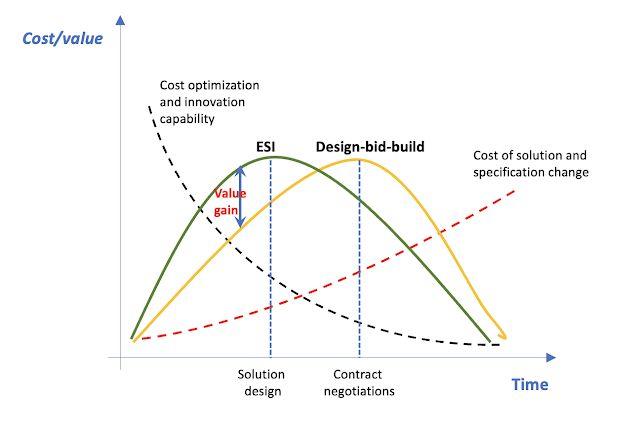

Key benefits of Early Supplier Involvement (ESI) in the logistics process include improved product quality, reduced lead times, enhanced supply chain visibility, and increased agility in responding to market changes. By working closely with suppliers on transportation, shipping, and warehousing solutions, companies can proactively address potential risks, optimize inventory levels, and enhance overall operational efficiency. Effective ESI strategies help organizations build stronger partnerships with suppliers, drive continuous improvement, and achieve competitive advantage in today’s dynamic business environment.

Maximizing Efficiency through Early Supplier Involvement in Transportation

Early Supplier Involvement (ESI) in the realm of transportation can significantly enhance efficiency and streamline operations. By collaborating with suppliers early in the process, businesses can leverage their expertise and resources to optimize transport strategies. This proactive approach ensures that all parties are aligned from the outset, leading to smoother transitions and improved performance.

Utilizing ESI in logistics, transport, and shipping can result in several key benefits, including:

- Improved cost-effectiveness: By involving suppliers early, businesses can identify cost-saving opportunities and negotiate favorable terms.

- Enhanced quality and reliability: Supplier input can help improve the quality of transportation services and ensure on-time delivery.

- Increased flexibility: Early collaboration allows for greater flexibility in adapting to changing market conditions or unforeseen challenges.

Optimizing Shipping Processes with Early Supplier Involvement Strategies

When it comes to optimizing shipping processes, early supplier involvement strategies can make a significant difference. By involving suppliers early in the planning and execution of shipping processes, businesses can streamline their operations, reduce costs, and improve overall efficiency. This collaborative approach allows suppliers to provide valuable insights, expertise, and resources that can help in designing and implementing more effective shipping solutions.

One key benefit of early supplier involvement in shipping processes is the ability to identify potential issues and challenges before they escalate. Suppliers can help businesses anticipate and address logistical hurdles, such as transportation delays, inventory shortages, and quality control issues. By working closely with suppliers from the outset, companies can proactively address these challenges and develop robust shipping strategies that meet their specific needs and requirements. Overall, early supplier involvement in shipping processes can lead to a more seamless and cost-effective supply chain operation.

Key Recommendations for Implementing Early Supplier Involvement in Logistics Operations

When implementing Early Supplier Involvement (ESI) in logistics operations, it is important to consider several key recommendations to ensure success. Firstly, establishing clear communication channels with suppliers early on is crucial. This will help in aligning goals and expectations, as well as allow for timely feedback and problem-solving.

Secondly, fostering a collaborative partnership with suppliers is essential for effective ESI. This means involving suppliers in the decision-making process, sharing relevant information, and seeking their input on logistics strategies. By working together towards common goals, companies can improve efficiency, reduce costs, and enhance overall supply chain performance.

In Retrospect

As we conclude our exploration of Early Supplier Involvement in logistics, transport, and shipping, we are reminded of the value of collaboration and partnership in creating efficient and sustainable supply chains. By involving suppliers early in the process, companies can streamline operations, reduce costs, and improve overall performance. As the world of supply chain management continues to evolve, it is clear that ESI is a key strategy to staying ahead of the curve. Embracing this approach will not only benefit individual businesses but also contribute to a more resilient and interconnected global economy. Thank you for joining us on this journey of discovery and innovation in logistics and transportation. Stay tuned for more insights and solutions to come.