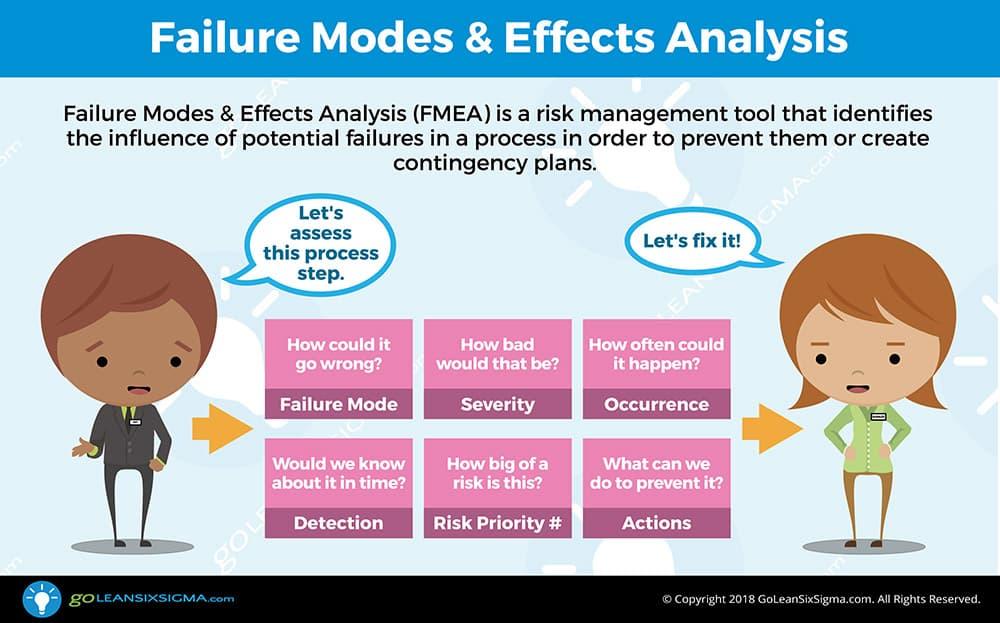

Navigating the intricate web of logistics, transport, and shipping can sometimes feel like traversing a minefield. One wrong move, one overlooked detail, and the entire operation can come crashing down. This is where Failure Modes Effects Analysis (FMEA) steps in as a vital tool for assessing and mitigating risks in the world of logistics. In this article, we will delve into the realm of FMEA as it pertains to the intricate dance of moving goods from point A to point B, exploring how this method can help ensure smooth sailing in the often turbulent waters of transportation and shipping.

Identifying Potential Failure Modes in Logistics Operations

When it comes to logistics operations, it is crucial to anticipate and identify potential failure modes that could impact the efficiency and effectiveness of transport and shipping processes. Conducting a Failure Modes Effects Analysis (FMEA) can help organizations proactively address vulnerabilities and mitigate risks in their logistics operations.

By analyzing the potential failure modes in logistics, companies can better understand the root causes of potential disruptions and develop strategies to prevent or minimize their impact. Some common failure modes in logistics operations include delays in transportation, inventory shortages, packaging failures, and communication breakdowns. By conducting an FMEA, organizations can prioritize areas for improvement and develop action plans to enhance the reliability and resilience of their logistics processes.

Analyzing the Effects of Failure on Transport Efficiency

Failure Modes Effects Analysis (FMEA) is a powerful tool used in the logistics, transport, and shipping industry to analyze the potential failure modes of a system and their effects on transport efficiency. By identifying possible failure modes and their impact, companies can proactively address issues before they occur, ultimately improving their overall operational performance.

Through FMEA, logistics professionals can prioritize and address critical failure modes that could lead to delays, increased costs, or even safety hazards. By conducting a thorough analysis, companies can implement preventive measures and contingency plans to mitigate the effects of failure on transport efficiency. By continuously monitoring and evaluating their processes, organizations can ensure smooth and seamless operations that meet customer expectations and drive business success.

Recommendations for Implementing FMEA in Shipping Processes

Implementing Failure Modes Effects Analysis (FMEA) in shipping processes can greatly enhance the efficiency and reliability of logistics operations. To effectively utilize FMEA in the shipping industry, it is important to follow these key recommendations:

- Engage Cross-functional Teams: Involving representatives from various departments such as logistics, operations, and quality control ensures a comprehensive analysis of potential failure modes and their effects on shipping processes.

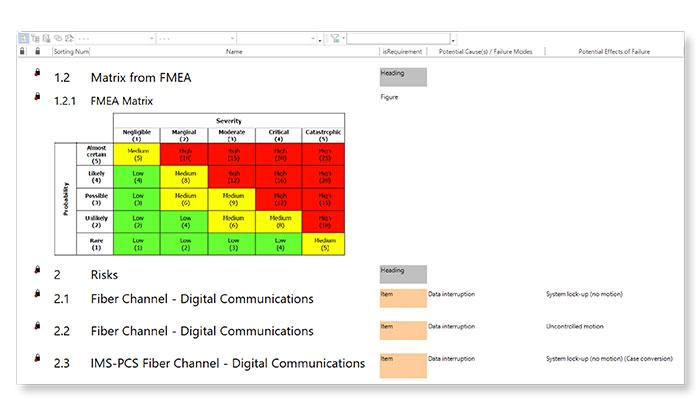

- Prioritize High-risk Areas: Identify critical failure modes that could have a significant impact on the shipping process, prioritize them based on severity and occurrence, and focus on mitigating these risks first.

| Failure Mode | Effect |

|---|---|

| Delayed Shipments | Customer dissatisfaction, loss of business |

| Incorrect Address Labeling | Delivery delays, increased shipping costs |

Benefits of Conducting FMEA in Logistics Management

When it comes to managing logistics, conducting Failure Modes Effects Analysis (FMEA) can provide a plethora of benefits. By identifying potential failure modes and their effects, logistics managers can proactively address issues, improve processes, and increase overall efficiency. Through FMEA, the logistics team can prioritize risks and implement preventive measures to minimize the likelihood of failures occurring during transport, shipping, and other logistics operations.

One of the key advantages of FMEA in logistics management is the ability to enhance decision-making processes. By analyzing potential failure modes and their effects, logistics managers can make more informed decisions that mitigate risks and improve overall performance. Additionally, conducting FMEA can help reduce costs associated with failures, improve customer satisfaction, and ultimately drive greater success in the logistics industry.

The Way Forward

In conclusion, Failure Modes Effects Analysis (FMEA) is a valuable tool for identifying potential risks and improving the efficiency of logistics, transport, and shipping operations. By analyzing failure modes and their effects, companies can mitigate risks and better manage their supply chain processes. This proactive approach to problem-solving can lead to cost savings, increased reliability, and ultimately, greater customer satisfaction. As the logistics industry continues to evolve, integrating FMEA into operational strategies can help businesses stay ahead of the curve and navigate any challenges that come their way. So, if you’re looking to optimize your logistics operations, consider employing FMEA to drive success in your shipping and transportation endeavors.