In the fast-paced world of logistics, efficiency is key. From warehouses to transportation, every step in the supply chain must be carefully orchestrated to ensure goods reach their destination in a timely and cost-effective manner. One tool that has proven invaluable in this process is the fixed quantity inventory model. By optimizing inventory levels and streamlining order fulfillment, this model can revolutionize the way companies approach logistics, transport, and shipping. Let’s explore how this innovative approach is reshaping the industry and helping businesses stay ahead of the competition.

Overview of the Fixed Quantity Inventory Model

In the world of logistics, transport, and shipping, utilizing the Fixed Quantity Inventory Model is crucial for businesses to efficiently manage their inventory. This model involves maintaining a set quantity of stock on hand at all times, replenishing it only when it drops below a predetermined level. By implementing this model, companies can streamline their supply chain operations, minimize stockouts, and optimize their inventory turnover rates.

With the Fixed Quantity Inventory Model, businesses can enjoy several benefits, such as:

- Reduced holding costs: By only stocking a fixed quantity of items, companies can minimize storage expenses and free up valuable warehouse space.

- Improved order fulfillment: Ensuring a constant supply of products enables businesses to fulfill orders promptly and maintain high customer satisfaction levels.

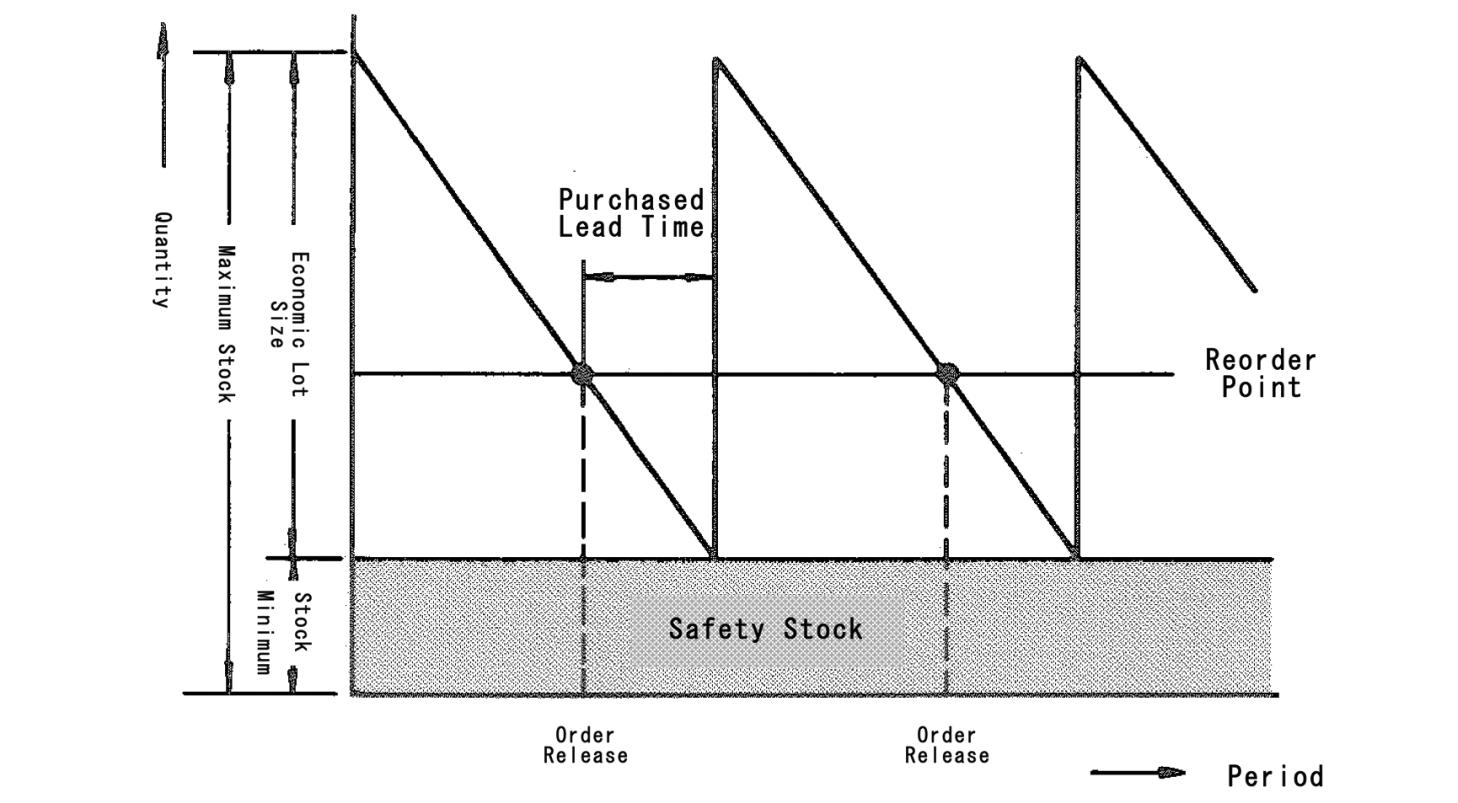

- Enhanced inventory control: With a clear understanding of stock levels and reorder points, organizations can better manage their inventory and avoid overstocking or understocking situations.

Benefits of Implementing the Fixed Quantity Inventory Model

Implementing the Fixed Quantity Inventory Model can bring numerous benefits to businesses in the logistics, transport, and shipping industries. One of the key advantages is improved inventory management efficiency. By setting fixed quantities for each product, companies can easily track their inventory levels and ensure they always have the right amount of stock on hand.

Another benefit of this model is reduced carrying costs. With a fixed quantity inventory system, companies can minimize excess inventory and avoid unnecessary storage expenses. This, in turn, leads to improved cash flow and higher profitability. Additionally, the fixed quantity model helps companies maintain leaner operations and reduce the risk of stockouts, ultimately leading to better customer satisfaction and loyalty.

Common Challenges in Fixed Quantity Inventory Management

One common challenge in fixed quantity inventory management is accurately forecasting demand. Without precise predictions, companies may end up with excess inventory that ties up capital or too little stock leading to stockouts. This challenge is particularly pronounced in industries with fluctuating demand or seasonal trends. Utilizing historical data, market research, and collaboration between departments can help improve demand forecasting accuracy.

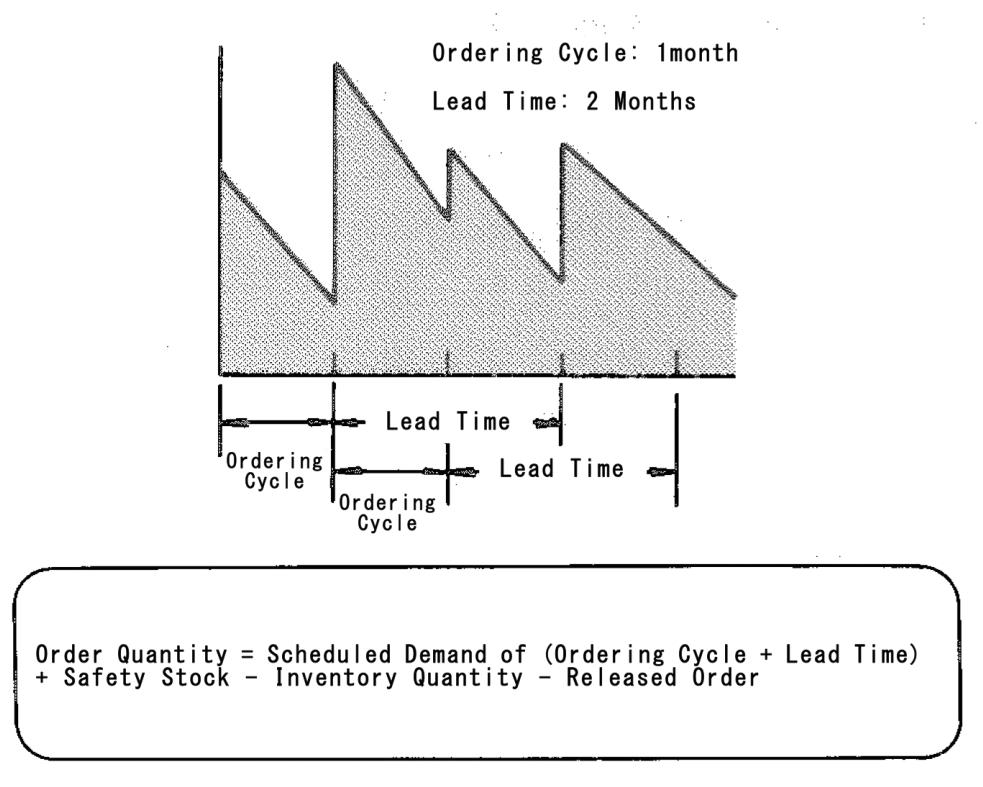

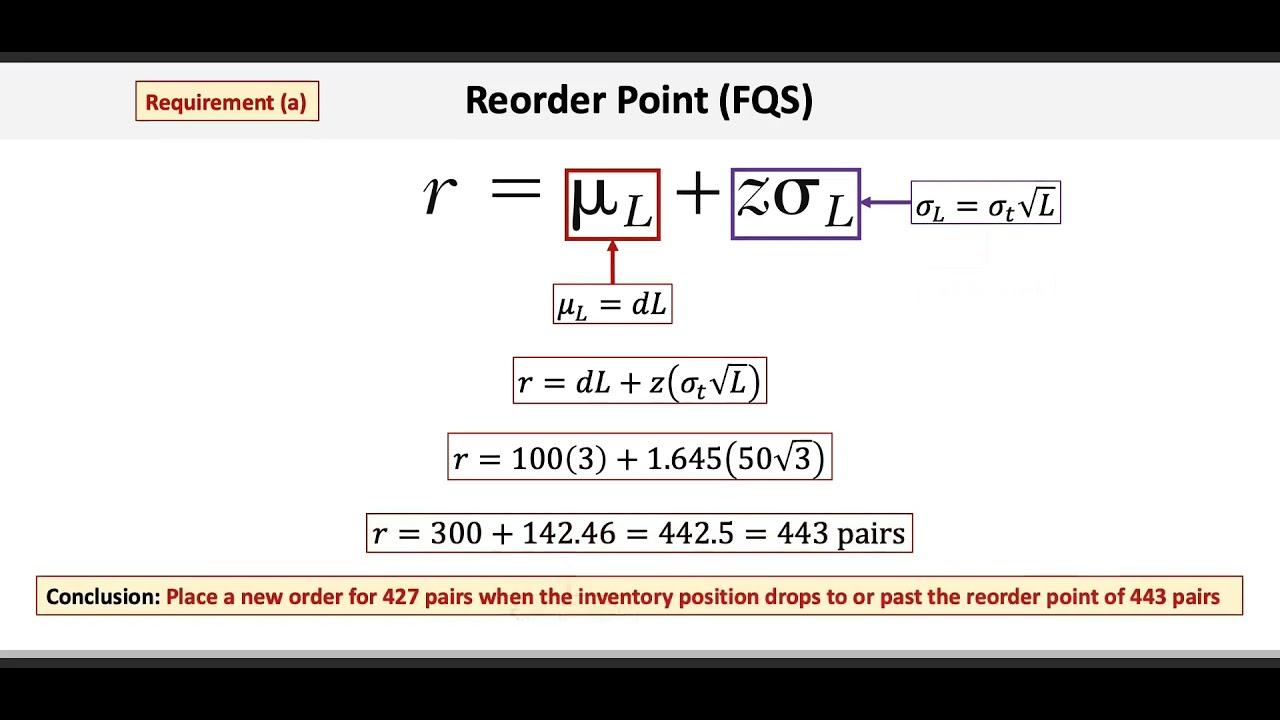

Another challenge is optimizing order quantities to minimize holding costs and stockouts. Determining the right balance between ordering too much and risking obsolescence versus ordering too little and facing stockouts is crucial. Implementing an efficient reorder point system, utilizing economic order quantity calculations, and leveraging technology such as inventory management software can aid in achieving optimal order quantities.

Recommendations for Optimizing Fixed Quantity Inventory Model Operations

When it comes to optimizing operations in a fixed quantity inventory model, there are several key recommendations to keep in mind. First and foremost, it is essential to closely monitor inventory levels to ensure that they are neither too high nor too low. By maintaining the right balance, businesses can prevent stockouts and overstock situations, ultimately maximizing efficiency.

Additionally, implementing a reliable forecasting system can greatly benefit fixed quantity inventory model operations. By accurately predicting demand trends and adjusting reorder points accordingly, companies can reduce lead times, improve customer satisfaction, and minimize carrying costs. Furthermore, regular evaluations of suppliers and transportation providers can help streamline logistics processes and enhance overall supply chain performance. By fostering strong partnerships and optimizing shipping routes, businesses can ensure timely deliveries and minimize transportation expenses.

The Way Forward

In conclusion, the fixed quantity inventory model is a crucial tool in logistics, transport, and shipping industries. By carefully managing inventory levels and ordering practices, businesses can optimize their supply chain efficiency and reduce costs. Implementing this model requires careful planning and monitoring, but the benefits of improved inventory management are well worth the effort. Remember, a well-balanced supply chain is the key to success in today’s competitive marketplace. Thank you for reading and good luck in applying these strategies to your own logistics operations.