In the world of logistics and shipping, the role of the warehouse is paramount. Often overlooked, the intermediately positioned warehouse plays a crucial role in the supply chain, serving as the linchpin between transportation and distribution. In this article, we will delve into the intricate and essential world of intermediately positioned warehouse logistics, shedding light on the inner workings of this dynamic industry. Join us as we explore the key strategies, challenges, and innovations that shape this vital component of global commerce.

Key Aspects of Intermediately Positioned Warehouse Logistics

The involve strategic placement of warehouses to optimize transportation and shipping processes. By strategically locating warehouses in between suppliers and customers, companies can reduce transportation costs and delivery times, ultimately improving overall efficiency.

<p>Some of the essential elements of intermediately positioned warehouse logistics include:</p>

<ul>

<li><strong>Inventory Management:</strong> Efficiently managing inventory levels to prevent stockouts and oversupply.</li>

<li><strong>Order Fulfillment:</strong> Ensuring timely and accurate order picking, packing, and shipping processes.</li>

<li><strong>Transportation Planning:</strong> Developing optimal transportation routes and modes to minimize costs and maximize delivery speed.</li>

<li><strong>Communication:</strong> Establishing clear communication channels between suppliers, warehouses, and customers to ensure smooth operations.</li>

</ul>

Efficient Transport Strategies for Intermediate Warehouse Facilities

When it comes to managing transport logistics for intermediate warehouse facilities, efficiency is key. By implementing strategic transportation strategies, businesses can streamline their operations and maximize their resources. One effective method is to utilize a combination of different modes of transport, such as trucks, trains, and ships, to optimize delivery routes and reduce costs.

Another important aspect to consider is the use of advanced technology solutions, such as GPS tracking systems and route optimization software, to monitor and manage shipments in real-time. By leveraging these tools, companies can ensure that their products are delivered in a timely manner while minimizing delays and disruptions. Additionally, establishing strong partnerships with reliable carriers and logistics providers can help streamline the transportation process and enhance overall operational efficiency.

Optimizing Shipping Processes in Intermediately Positioned Warehouse Settings

One key aspect of is to first streamline the flow of goods within the warehouse itself. By strategically organizing inventory and creating efficient picking routes, you can drastically reduce the time it takes to fulfill orders. Implementing a barcode scanning system can also help to minimize errors and increase the overall speed of operations.

Another important factor to consider is the selection of the most cost-effective shipping methods. By analyzing data on shipping costs and transit times, you can determine the most efficient carriers for various destinations. Additionally, consolidating shipments whenever possible can help to reduce overall shipping costs and improve delivery times. Embracing technology such as transportation management software can also provide valuable insights into shipment tracking and performance metrics, allowing for continuous improvements in your shipping processes.

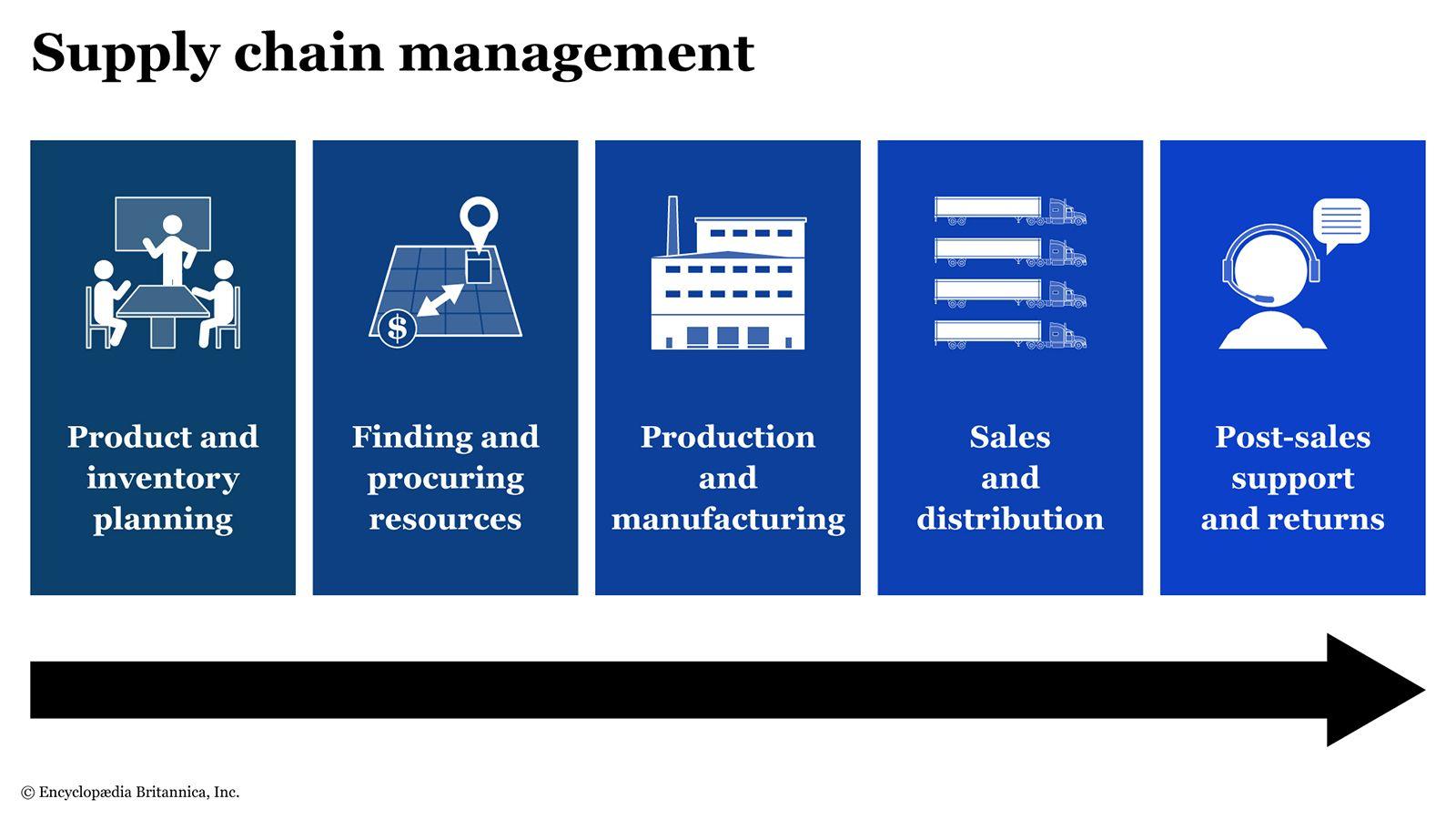

Recommendations for Enhancing Supply Chain Performance in Intermediately Positioned Warehouses

When looking to enhance supply chain performance in intermediately positioned warehouses, there are several recommendations to consider. Firstly, implementing a robust inventory management system can help optimize stock levels and reduce excess inventory. This can lead to improved efficiency and reduced costs in the long run. Additionally, investing in advanced technology such as RFID tags and barcode scanning can provide real-time visibility of inventory, leading to better decision-making and streamlined operations.

Another recommendation is to establish strong relationships with reliable transportation and shipping partners. By working closely with trusted providers, warehouses can ensure timely delivery of goods and minimize disruptions in the supply chain. Furthermore, conducting regular performance evaluations and implementing continuous improvement initiatives can help identify areas for optimization and drive overall efficiency in warehouse operations.

Wrapping Up

In conclusion, intermediately positioned warehouse logistics play a crucial role in streamlining the transport and shipping process. By strategically locating warehouses between suppliers and end customers, companies can reduce transportation costs, minimize delivery times, and improve overall efficiency. Embracing this approach can give businesses a competitive edge in the fast-paced world of logistics and help them meet the ever-changing demands of the market. As the industry continues to evolve, finding innovative solutions like intermediately positioned warehouse logistics will be key to staying ahead of the curve. So, next time you think about your logistics strategy, consider the benefits of this approach and how it can help your business thrive in the complex web of supply chain management. Stay tuned for more insights and updates on the latest trends in warehouse logistics and transport!