In the heart of the bustling world of commerce lies a vital component often overlooked but crucial for success – Inventory Turnover. A well-oiled machine of logistics, transport, and shipping, Inventory Turnover ensures that goods flow seamlessly from suppliers to customers, maximizing efficiency and profit. Join us as we explore the intricate dance of inventory management and learn how it plays a pivotal role in the supply chain ecosystem.

Maximizing Inventory Turnover in Logistics Operations

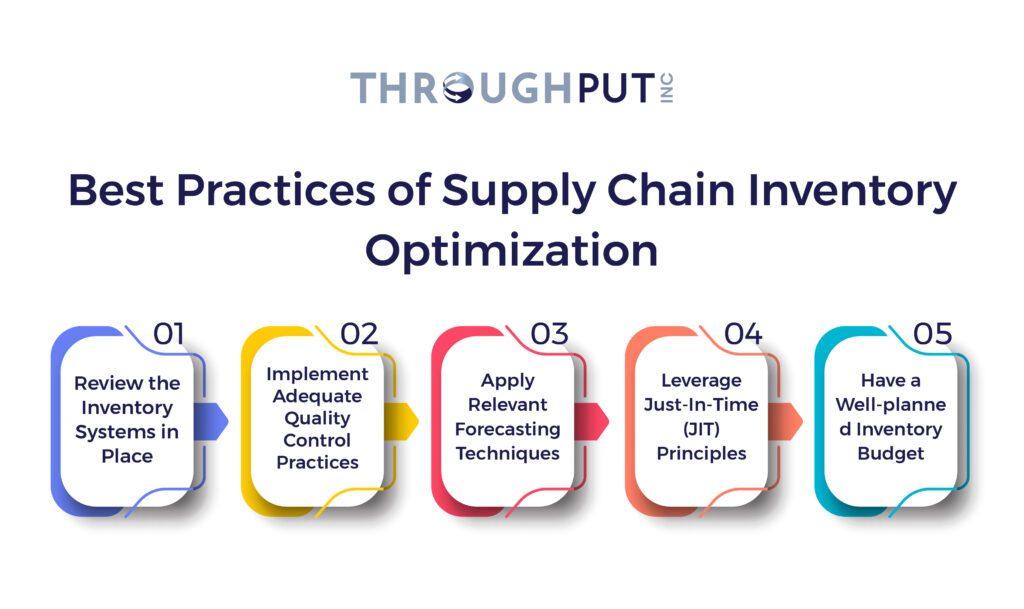

One effective way to maximize inventory turnover in logistics operations is by implementing efficient storage and inventory management systems. By utilizing smart storage solutions such as vertical shelving, automated picking systems, and RFID technology, businesses can optimize their warehouse space and streamline the process of locating and retrieving products. Additionally, investing in inventory forecasting software can help businesses anticipate demand and ensure that the right amount of inventory is always on hand.

Another key strategy for maximizing inventory turnover is to establish strong relationships with suppliers and streamline the supply chain process. By working closely with suppliers to implement just-in-time inventory practices, businesses can reduce excess inventory and minimize holding costs. Additionally, leveraging advanced logistics technologies such as route optimization software and real-time tracking systems can help businesses improve transportation efficiency and reduce lead times.

Implementing Efficient Transport Strategies for Faster Inventory Turnover

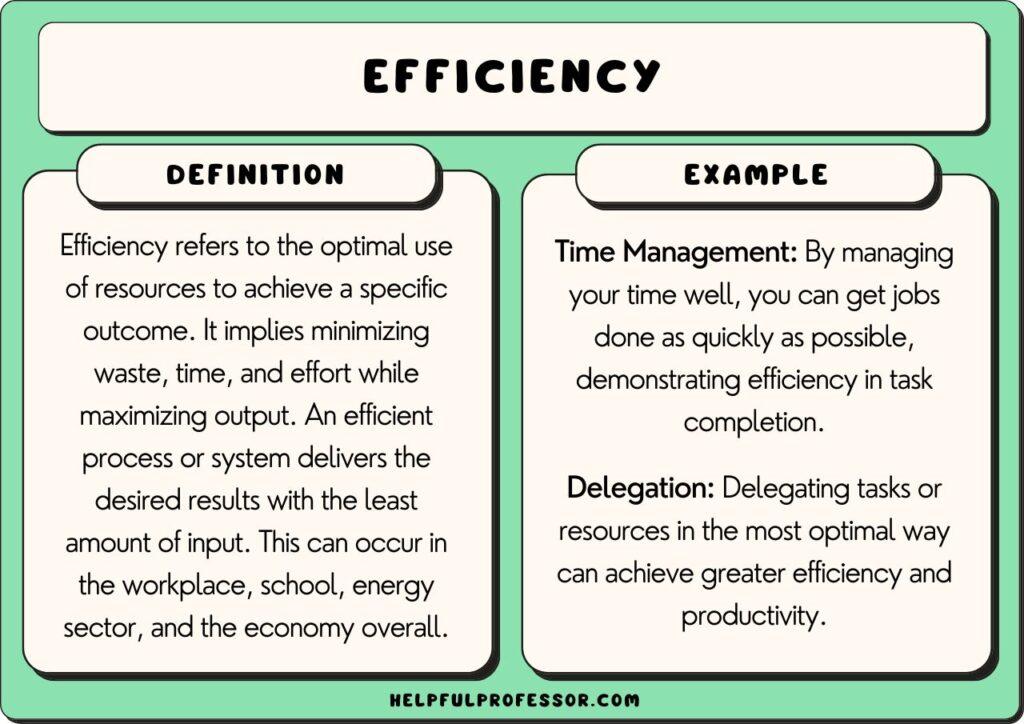

Implementing efficient transport strategies is essential for faster inventory turnover. By optimizing your logistics process, you can reduce lead times, minimize transportation costs, and improve overall efficiency in your supply chain. Utilizing a combination of transportation modes such as air, sea, rail, and road can help streamline the movement of goods and ensure timely delivery to customers.

One effective strategy is to use a combination of just-in-time delivery and cross-docking to reduce excess inventory and improve cash flow. By coordinating shipments to arrive precisely when needed, you can minimize storage costs and improve inventory turnover rates. Additionally, investing in real-time tracking and monitoring technology can provide visibility into your supply chain, allowing you to make data-driven decisions and optimize transportation routes for maximum efficiency. By implementing these transport strategies, you can speed up inventory turnover and stay competitive in today’s fast-paced market.

| Transport Mode | Advantages |

|---|---|

| Road | Flexible and cost-effective |

| Sea | Ideal for bulky shipments |

| Rail | Efficient for long-distance transportation |

| Air | Fastest mode of transport |

Optimizing Shipping Processes for Improved Inventory Turnover Results

When it comes to , there are several key strategies that can be implemented to streamline operations and increase efficiency. One important factor to consider is the utilization of advanced inventory management systems that can track and manage inventory levels in real-time. By implementing such systems, businesses can minimize excess stock and reduce the risk of stockouts, leading to better turnover rates. Additionally, implementing automated shipping processes can help to reduce errors and delays, further improving inventory turnover results.

Another crucial aspect of optimizing shipping processes is to establish strong relationships with reliable shipping partners. By working closely with trusted carriers and logistics providers, businesses can ensure timely deliveries and reduce transportation costs. Utilizing data analytics to track shipping performance and identify opportunities for improvement can also be beneficial in .

Key Recommendations for Streamlining Inventory Turnover in the Logistics Industry

When it comes to streamlining inventory turnover in the logistics industry, there are several key recommendations that can help improve efficiency and profitability. One important strategy is to optimize warehouse layout and organization to ensure quick and easy access to inventory items. By implementing a more efficient storage system, companies can reduce picking and packing times, leading to faster inventory turnover.

Another crucial recommendation is to use technology to track and manage inventory levels accurately. Utilizing inventory management software can provide real-time data on stock levels, customer demand, and order fulfillment. This can help companies make informed decisions regarding inventory purchasing, reducing excess stock and minimizing stockouts.

Key Takeaways

As we have seen, inventory turnover plays a crucial role in the success of logistics, transport, and shipping companies. By effectively managing and optimizing their inventory turnover, businesses can reduce costs, improve efficiency, and ultimately enhance customer satisfaction. Keeping a close eye on key performance indicators such as inventory turnover ratio and days inventory outstanding is essential for staying competitive in today’s fast-paced market. So, next time you’re strategizing your inventory management approach, remember the importance of turnover and its impact on your overall supply chain success. Here’s to smooth sailing and timely deliveries!