In the complex world of supply chain management, one crucial element often overlooked is the role of Material Requirements Planning (MRP) in logistics, transport, and shipping. From coordinating the movement of raw materials to ensuring timely delivery of finished products, MRP plays a pivotal role in optimizing the flow of materials through the supply chain. In this article, we will delve into the world of MRP and explore how it impacts the intricate dance of logistics, transport, and shipping.

Understanding Material Requirements Planning (MRP) for Efficient Logistics

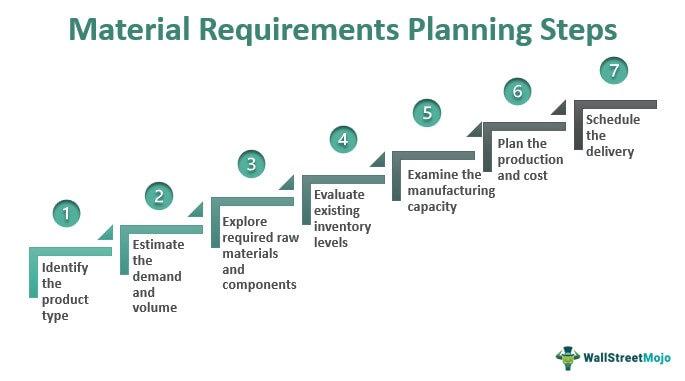

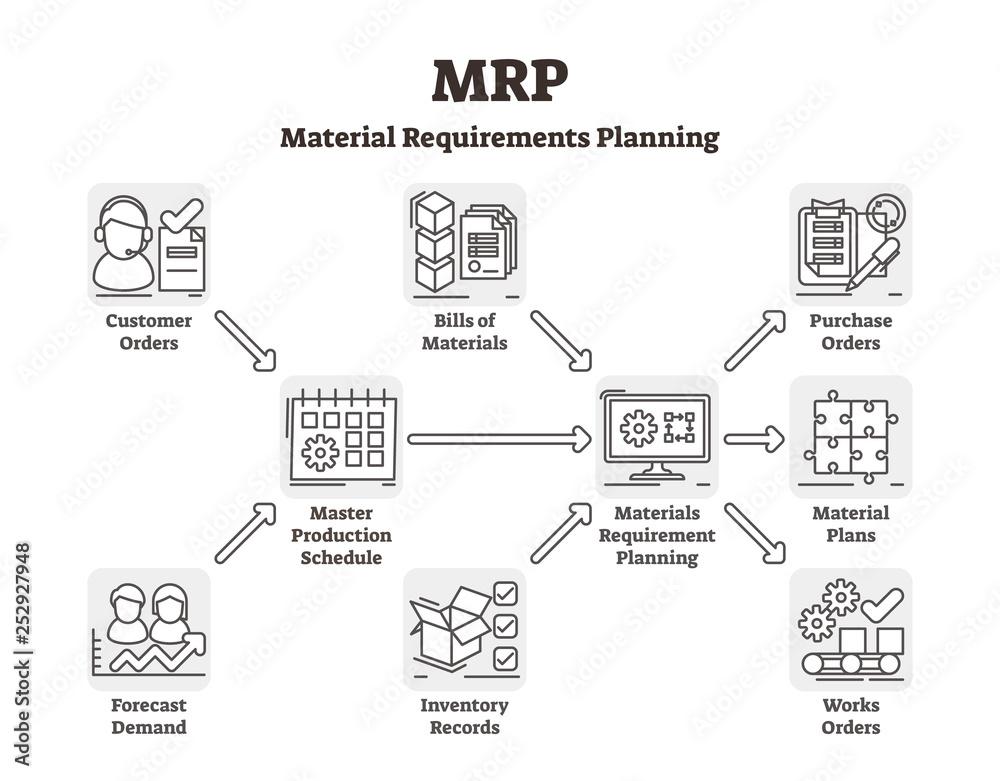

Material Requirements Planning (MRP) is a crucial aspect of efficient logistics management. By accurately forecasting the materials needed for production, companies can optimize their inventory levels, reduce lead times, and minimize stockouts. This advanced planning system ensures that the right materials are available at the right time, helping to streamline the entire supply chain process.

- MRP helps companies avoid overstocking or understocking inventory.

- By analyzing demand forecasts, production schedules, and lead times, MRP can improve production efficiency.

- MRP can also assist in identifying bottlenecks in the supply chain, allowing for better resource allocation.

When implemented effectively, Material Requirements Planning can enhance overall operational efficiency and reduce costs associated with inventory management. By leveraging technology and data analytics, companies can gain a competitive edge in today’s fast-paced logistics landscape.

Optimizing Transport Routes to Enhance MRP Effectiveness

When it comes to ensuring the effectiveness of Material Requirements Planning (MRP), optimizing transport routes plays a crucial role. By streamlining logistics and shipping processes, businesses can improve efficiency and reduce costs. One key strategy is to utilize advanced route optimization software that takes into account factors such as traffic patterns, delivery schedules, and vehicle capacity.

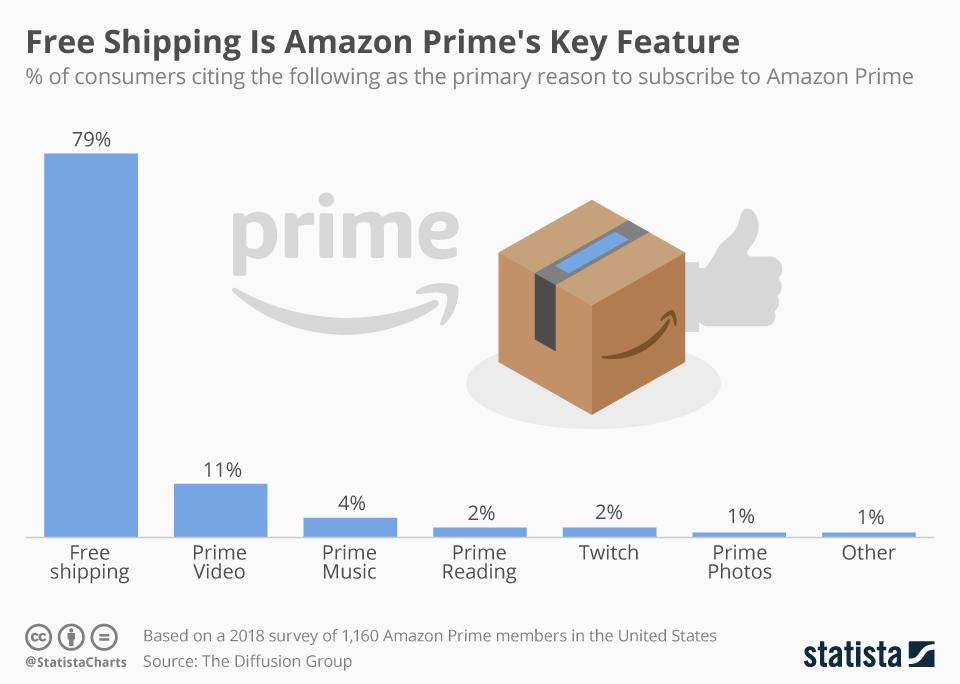

Additionally, companies can benefit from establishing partnerships with reliable transport providers to ensure timely deliveries and minimize disruptions. By implementing real-time tracking systems and leveraging data analytics, organizations can make informed decisions to enhance MRP effectiveness. Ultimately, proper logistics management and transport optimization can lead to improved inventory control, reduced lead times, and increased customer satisfaction.

Incorporating Shipping Strategies into Material Requirements Planning

involves considering various factors such as transport costs, lead times, and carrier reliability. By optimizing shipping strategies within MRP, businesses can streamline their supply chain operations and improve overall efficiency.

Key considerations for incorporating shipping strategies into MRP include:

- Mode of transport: Choosing the most cost-effective and efficient transportation mode for different types of materials.

- Shipping schedules: Aligning shipping schedules with production schedules to minimize delays and optimize inventory levels.

- Carrier selection: Evaluating carriers based on performance metrics, pricing, and service quality.

Key Recommendations for Seamless MRP Logistics Integration

When integrating Material Requirements Planning (MRP) with logistics, it is crucial to follow key recommendations to ensure a seamless process. One of the main recommendations is to prioritize communication between the MRP system and the logistics department. This can be achieved by establishing clear channels of communication and ensuring that both teams are aligned with their goals and objectives.

Another important recommendation is to utilize automation tools to streamline the logistics integration process. By leveraging automation software, companies can improve efficiency, reduce manual errors, and enhance overall productivity. Additionally, investing in training programs for employees to understand both MRP and logistics systems can further optimize performance and ensure a successful integration.

The Conclusion

In conclusion, Material Requirements Planning (MRP) plays a crucial role in the logistics, transport, and shipping industries by efficiently managing inventory levels and ensuring timely delivery of goods. By implementing MRP systems, companies can streamline their supply chain operations and enhance their overall productivity. As technology continues to advance, the future of MRP looks promising as it continues to revolutionize the way businesses manage their materials and resources. Stay tuned for more updates on the latest trends and developments in MRP logistics. Thank you for reading!