In the vast world of commerce, the art of efficient logistics, transport, and shipping is nothing short of a marvel. From the bustling warehouses where goods are stored to the intricate network of transportation that spans continents, the process of getting products from point A to point B is a complex dance of precision and coordination. Join us as we dive into the world of “Put Away Logistics – Transport – Shipping” and discover the inner workings of this crucial pillar of modern business.

Improving Efficiency in Put Away Processes

When it comes to , there are several key strategies that can be implemented to streamline operations and optimize workflow. One of the most effective ways to enhance efficiency is by utilizing advanced technologies such as automated storage and retrieval systems (AS/RS) and warehouse management systems (WMS). These technologies can help minimize errors, reduce manual handling, and increase the speed at which items are put away.

Additionally, creating standardized procedures and workflows for put away processes can also make a significant impact on efficiency. By establishing clear guidelines and best practices for employees to follow, organizations can ensure that items are stored in the correct locations, reducing the time spent searching for misplaced items. Regular training and performance evaluations can further help to improve accuracy and speed in put away processes.

Streamlining Warehouse Logistics for Optimal Performance

When it comes to optimizing warehouse logistics for peak performance, one of the key areas to focus on is the put-away process. Efficiently storing incoming inventory in the right locations can significantly impact overall operations. By implementing strategic put-away procedures, companies can streamline their warehouse operations and improve productivity.

One effective strategy is to utilize a cross-docking approach, where incoming goods are immediately sorted and transferred to outbound shipping areas without being stored in the warehouse. This minimizes handling and storage time, reducing the risk of errors and improving efficiency. Another important aspect is implementing a location-based put-away system, where items are stored based on their size, weight, and frequency of retrieval. By organizing inventory in a logical manner, companies can minimize picking time and improve order fulfillment rates.

The Role of Transport in Seamless Shipping Operations

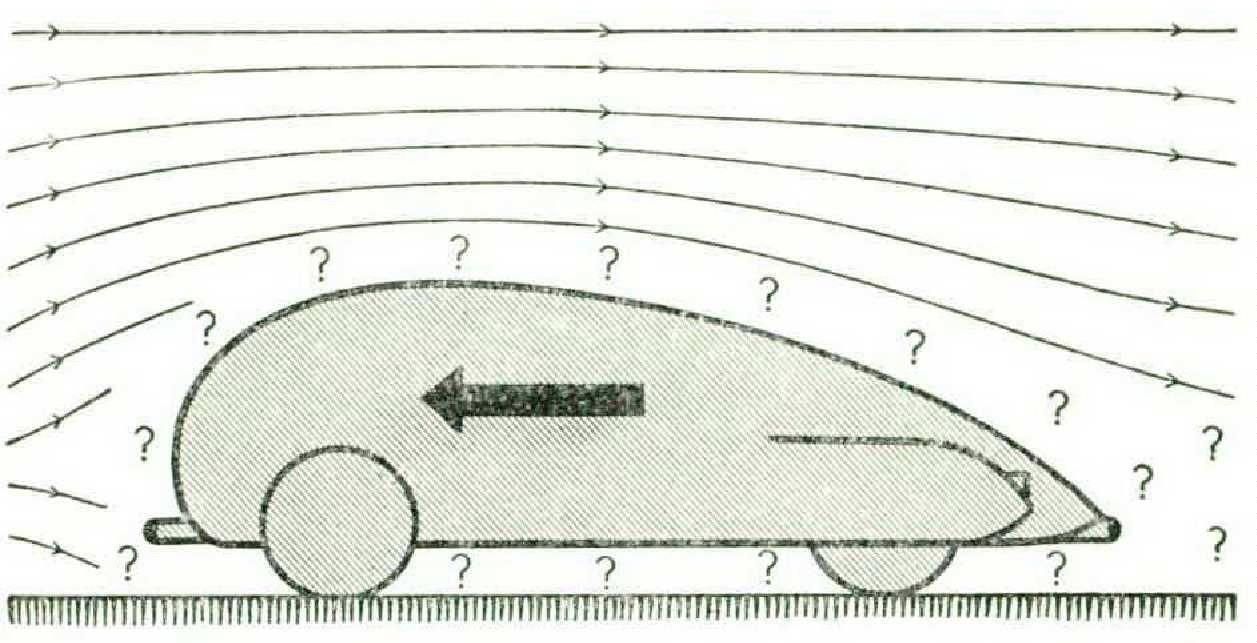

Transport plays a crucial role in ensuring seamless shipping operations. Whether by road, rail, air, or sea, the movement of goods from one point to another is essential for the success of any logistics process. Efficient transportation enables timely delivery, reduces costs, and improves overall customer satisfaction. With advances in technology and the integration of smart solutions, transport has become a key factor in optimizing supply chain management.

When it comes to shipping, the right transport mode can make all the difference. From trucks and trains to planes and ships, each mode offers unique benefits depending on the nature of the cargo, distance, and urgency of delivery. By leveraging a combination of transport modes and utilizing advanced tracking systems, companies can enhance visibility, reduce transit times, and minimize the risk of delays. In today’s fast-paced world, where speed and reliability are paramount, effective transport management is the key to unlocking seamless shipping operations.

Strategic Recommendations for Enhancing Put Away Processes

When it comes to enhancing put away processes, there are several strategic recommendations that can help streamline operations and improve efficiency. One key recommendation is to establish clear guidelines and standard operating procedures for put away tasks. This can help ensure consistency and accuracy in the placement of goods within the warehouse. Additionally, investing in technology such as RFID tracking systems can help automate the put away process, reducing the potential for human error.

Another important recommendation is to optimize the layout of the warehouse to minimize travel time for workers during put away tasks. This can be achieved by grouping similar items together and organizing inventory in a logical manner. Implementing a first-in-first-out (FIFO) system can also help ensure that older inventory is put away first, reducing the risk of stock obsolescence. By incorporating these strategic recommendations, businesses can improve the efficiency and effectiveness of their put away processes, ultimately leading to cost savings and improved customer satisfaction.

Future Outlook

In conclusion, effective logistics, transport, and shipping are essential components of any successful business operation. By putting away any inefficiencies or obstacles that may hinder the seamless flow of goods and services, companies can ensure timely deliveries, cost savings, and ultimately, customer satisfaction. So, remember to prioritize your logistics strategy, streamline your transport processes, and optimize your shipping operations to stay ahead in today’s competitive market. Thank you for reading!