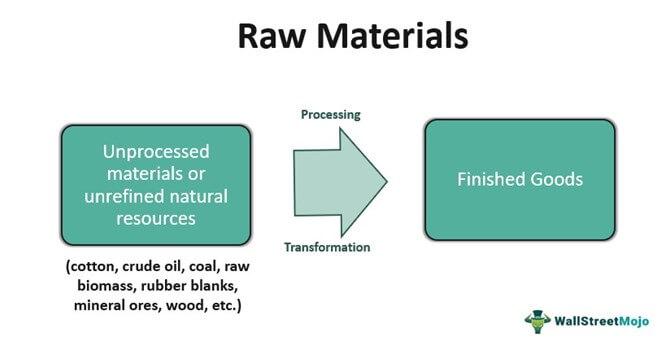

In the intricate dance of global trade, one often overlooked yet essential player quietly orchestrates the movement of vital resources – Raw Materials (RM) Logistics. From the sprawling quarries of remote mountains to the bustling ports of major cities, the intricate process of transporting and shipping raw materials is a crucial component of our modern economy. Join us on a journey through the intricate web of RM logistics, where every step is carefully planned and executed to ensure the smooth flow of essential resources across the globe.

Optimizing Raw Materials Logistics for Cost-Efficiency

Raw Materials (RM) Logistics – Transport - Shipping

Optimizing raw materials logistics is essential for businesses looking to reduce costs and improve efficiency in their operations. By streamlining the transportation and shipping processes for raw materials, companies can lower expenses and increase profitability. One way to achieve this is by strategically planning the movement of raw materials from suppliers to production facilities, warehouses, and distribution centers.

Effective raw materials logistics involves evaluating different transportation options, optimizing shipping routes, and implementing cost-effective strategies. By utilizing advanced logistics technology and data analytics, companies can track and monitor raw materials in real-time, identify potential bottlenecks or delays, and proactively address issues to ensure smooth and timely delivery. Additionally, establishing strong partnerships with reliable suppliers and carriers can help minimize transportation costs and improve overall efficiency in the supply chain.

Suppliers Collaboration for Streamlined Transport Processes

Collaborating with suppliers is crucial for ensuring smooth and efficient transport processes for raw materials. By working together closely, we can streamline logistics, transportation, and shipping to enhance overall supply chain efficiency. Through effective communication and coordination, we can minimize delays, reduce costs, and improve overall productivity.

Some key strategies for suppliers collaboration in raw materials logistics include:

- Regular Communication: Keeping open lines of communication between suppliers and transportation partners is essential for addressing any issues or changes in a timely manner.

- Collaborative Planning: Working together to plan shipments, routes, and schedules can help optimize transport processes and minimize disruptions.

- Information Sharing: Sharing relevant data and information between suppliers and transportation providers can help improve visibility and tracking throughout the supply chain.

Sustainable Shipping Practices in Raw Materials Management

Sustainable shipping in raw materials management is crucial for minimizing environmental impact and promoting responsible resource use. By implementing eco-friendly practices in RM logistics, transport, and shipping, companies can contribute to a greener, more sustainable future. One key aspect of sustainable shipping is the use of low-emission transportation, such as electric vehicles or ships powered by alternative fuels like biofuels or hydrogen.

Another important consideration is the optimization of shipping routes to reduce unnecessary mileage and emissions. Collaboration with suppliers to streamline transportation processes and minimize packaging materials can also help reduce the carbon footprint of raw material shipping. By adopting sustainable practices in RM logistics, companies can make a positive impact on the environment while also enhancing their reputation as responsible stewards of the planet.

Strategic Warehouse Placement for Improved RM Logistics

When it comes to efficiently managing raw materials logistics, strategic warehouse placement plays a crucial role in ensuring streamlined operations. By strategically locating warehouses in key areas, businesses can minimize transportation costs, reduce lead times, and improve overall supply chain efficiency. This strategic approach involves carefully analyzing factors such as proximity to suppliers, transportation routes, and customer demand centers.

With the right warehouse placement, businesses can optimize inventory management, reduce stockouts, and enhance customer satisfaction. By strategically positioning warehouses near production facilities or distribution centers, companies can minimize handling and storage costs while maximizing operational efficiency. Additionally, strategic warehouse placement allows businesses to respond quickly to market demand fluctuations and optimize shipping routes for cost-effective transportation.

Closing Remarks

In conclusion, raw materials logistics, transport, and shipping play a critical role in ensuring the smooth operation of supply chains and the efficient delivery of goods. By understanding the complexities and challenges associated with managing raw materials, companies can better streamline their processes and reduce costs. From sourcing to delivery, every step in the logistics chain must be carefully coordinated to ensure that raw materials reach their intended destination in a timely manner. With careful planning and coordination, companies can optimize their raw materials logistics and maintain a competitive edge in today’s fast-paced global marketplace.