In the fast-paced world of manufacturing, efficiency is key. Shop floor production control systems have revolutionized the way companies manage their logistics, transport, and shipping processes. From tracking inventory levels to monitoring production schedules, these systems are the backbone of successful supply chain management. Join us as we explore the intricate dance of technology and production on the shop floor, and how these systems are shaping the future of manufacturing.

Maximizing Efficiency with Shop Floor Production Control Systems

Implementing shop floor production control systems can revolutionize the way a manufacturing facility operates. By utilizing advanced technology and automation, businesses can streamline their production processes, minimize downtime, and maximize efficiency. With real-time monitoring and data analysis, managers can make informed decisions that optimize workflows and improve overall productivity.

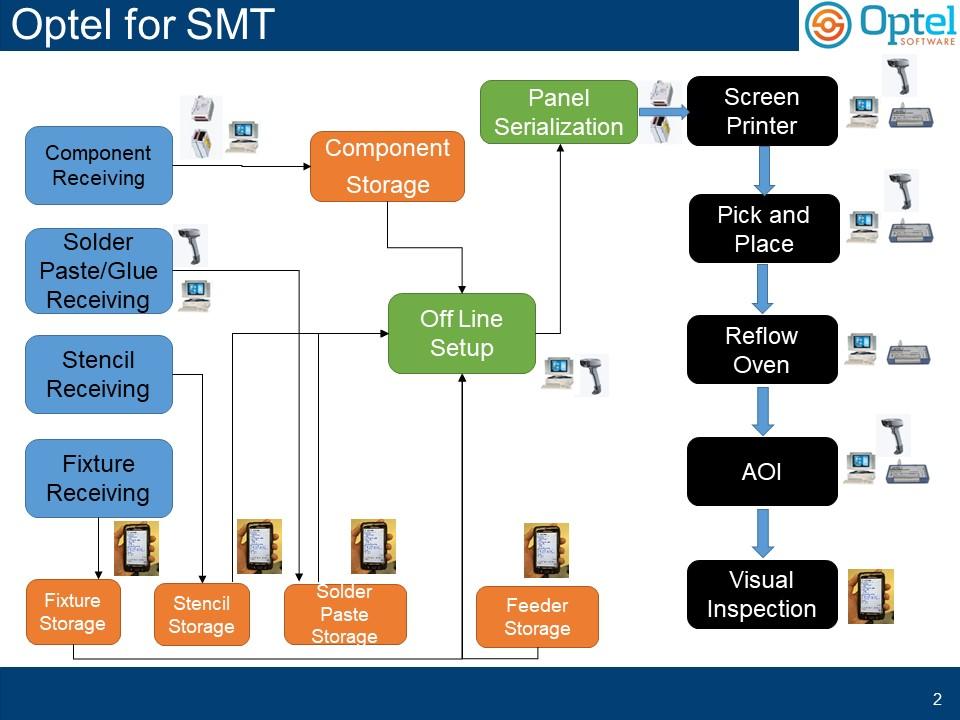

One of the key benefits of shop floor production control systems is the ability to track and trace every aspect of the production process. From inventory management to product quality control, these systems provide a comprehensive view of operations. Additionally, by integrating with other logistics and shipping systems, businesses can ensure seamless coordination from the shop floor to the final destination. By leveraging these advanced technologies, companies can stay competitive in today’s fast-paced manufacturing environment.

Streamlining Operations and Improving Productivity in Logistics

Implementing shop floor production control systems is essential in optimizing operations and increasing productivity in the logistics industry. These systems help in tracking and monitoring the production process, ensuring that goods are produced efficiently and according to schedule. By streamlining operations through the use of technology, companies can reduce waste, minimize errors, and meet customer demands in a timely manner.

Logistics, transport, and shipping companies can benefit greatly from the integration of production control systems. With real-time data and analytics, managers can make informed decisions to improve workflow, allocate resources effectively, and maximize output. By investing in technology that enhances visibility and communication, companies can stay ahead of the competition and deliver exceptional service to their clients.

Enhancing Shipping Processes: How Transport Systems Can Boost Efficiency

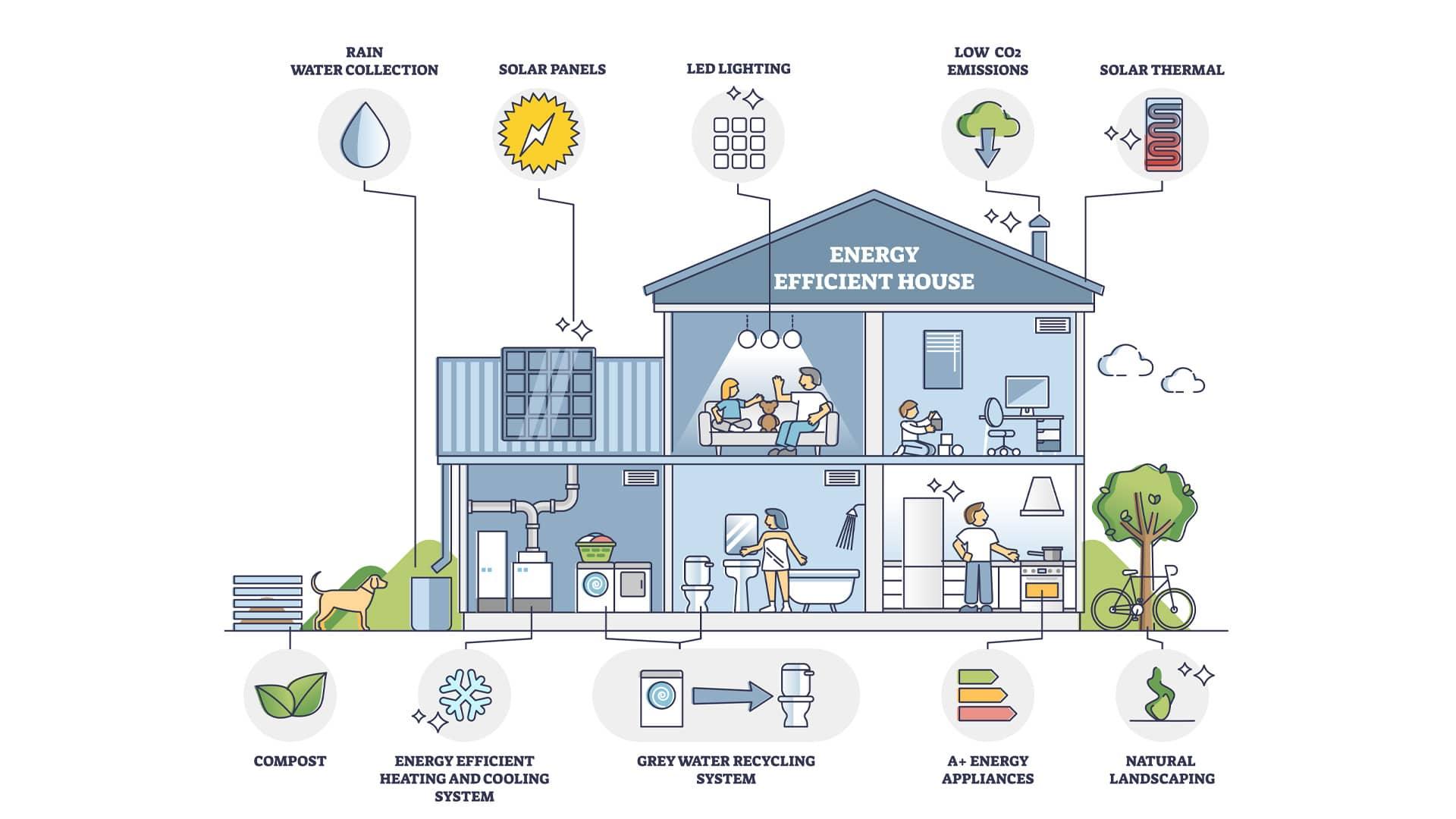

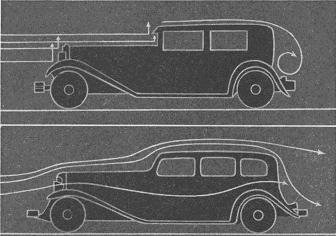

Implementing shop floor production control systems can significantly enhance shipping processes by streamlining operations and improving efficiency. These systems help track inventory levels, monitor production schedules, and optimize workflow to ensure timely delivery of products. By integrating transport systems with shop floor production control, companies can reduce lead times, minimize disruptions, and boost overall productivity.

With the use of advanced technology such as RFID tags and GPS tracking, transport systems can provide real-time visibility into the location and status of shipments. This level of transparency allows for better coordination between manufacturers, suppliers, and shipping carriers, ultimately leading to faster and more reliable deliveries. By leveraging automation and data analytics, companies can make informed decisions, identify bottlenecks, and implement continuous improvements to drive operational excellence in their shipping processes.

Implementing Advanced Technologies for Better Control and Integration

is crucial in today’s fast-paced manufacturing environment. Shop floor production control systems play a vital role in streamlining operations and optimizing efficiency. By leveraging cutting-edge technologies, manufacturers can enhance their logistics, transport, and shipping processes to meet the demands of a dynamic market.

One key aspect of implementing advanced technologies is the use of real-time data analytics to monitor production levels and identify bottlenecks. With Internet of Things (IoT) sensors and cloud-based platforms, manufacturers can access up-to-date information on inventory levels, machine performance, and order status. This data-driven approach enables better decision-making and resource allocation, leading to improved overall productivity and customer satisfaction. By integrating shop floor production control systems with logistics, transport, and shipping solutions, manufacturers can achieve seamless coordination and optimization across the entire supply chain.

Closing Remarks

In conclusion, Shop Floor Production Control Systems play a crucial role in ensuring smooth operations and efficient workflow in the manufacturing industry. By integrating logistics, transport, and shipping processes into a cohesive system, businesses can streamline their operations and improve overall productivity. With the right tools and technology in place, companies can achieve greater efficiency and cost savings, ultimately leading to a more competitive edge in the market. Embracing innovative solutions and staying ahead of the curve is key to success in today’s dynamic business environment. So, don’t hesitate to invest in the latest Shop Floor Production Control Systems to propel your business towards success.