As businesses strive for efficiency and cost savings in today’s fast-paced world of commerce, a unique approach to inventory management has emerged as a game-changer: Vendor-Managed Inventory (VMI). By forging strong partnerships and embracing innovative logistics solutions, companies are revolutionizing the way goods are transported and shipped. In this article, we will explore the ins and outs of VMI logistics and how it is reshaping the supply chain landscape. Join us on a journey through the world of VMI, where collaboration meets creativity and success knows no bounds.

Overview of Vendor-Managed Inventory (VMI)

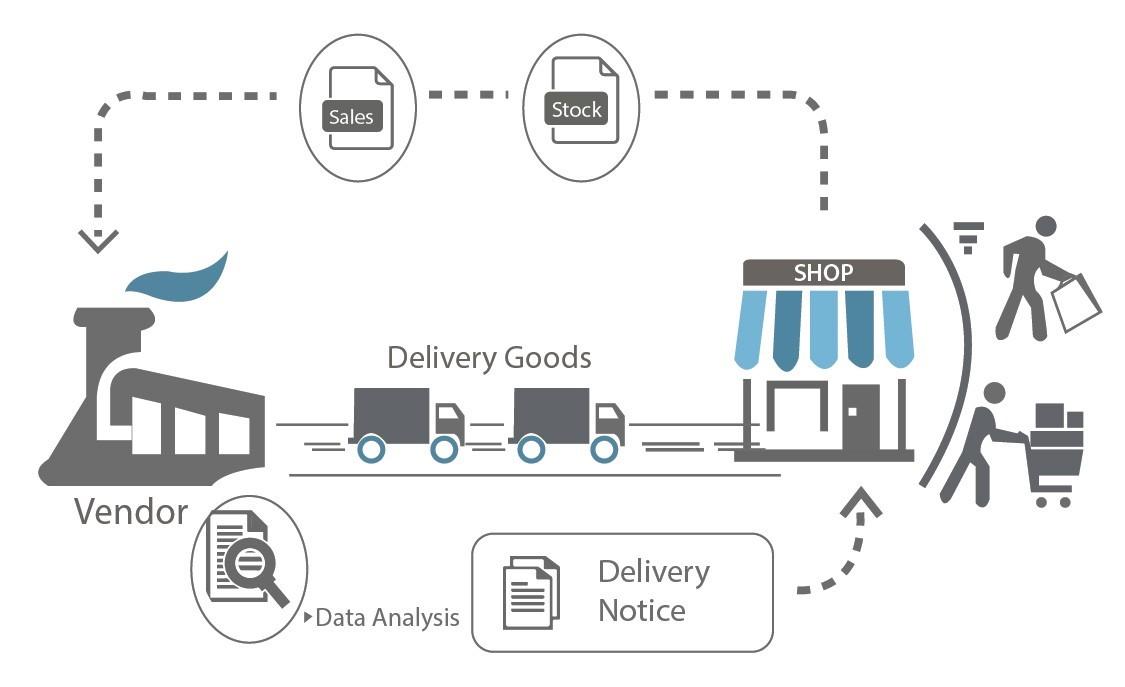

Vendor-Managed Inventory (VMI) is a supply chain management strategy where the vendor is responsible for monitoring and replenishing the customer’s inventory. This arrangement allows the vendor to have real-time visibility of inventory levels, enabling them to proactively manage stock levels, reduce stockouts, and improve overall supply chain efficiency. The goal of VMI is to streamline the replenishment process, reduce carrying costs, and strengthen the partnership between vendor and customer.

With VMI, the vendor takes on the responsibility of inventory management, ensuring that the customer always has the right amount of stock on hand. This helps to improve order accuracy, reduce lead times, and minimize the risk of overstocking or stockouts. By leveraging a collaborative approach to inventory management, both parties can benefit from improved supply chain performance, increased product availability, and lower overall costs.

Benefits of Implementing VMI in Logistics

One major benefit of implementing VMI in logistics is improved inventory management. With VMI, suppliers take on the responsibility of monitoring and replenishing inventory levels for their customers. This leads to reduced stockouts and overstock situations, ultimately optimizing inventory levels and reducing carrying costs.

Another advantage of VMI in logistics is increased supply chain efficiency. By allowing suppliers to have real-time visibility into their customers’ inventory levels, they can proactively plan and adjust production and transportation schedules. This results in smoother operations, reduced lead times, and improved overall supply chain performance.

Challenges in Transporting and Shipping VMI Goods

One of the biggest challenges in transporting and shipping Vendor-Managed Inventory (VMI) goods is ensuring timely delivery to meet the demand of the customers. Since the VMI model relies on the supplier managing the inventory levels at the customer’s location, any delays in transportation can result in stockouts or overstock situations. This can lead to customer dissatisfaction and lost sales opportunities, making it crucial for companies to have efficient logistics and shipping processes in place.

Another challenge in VMI logistics is the coordination between multiple parties involved in the supply chain. From suppliers to transportation providers to customers, there needs to be seamless communication and collaboration to ensure that goods are delivered accurately and on time. Any breakdown in communication can lead to disruptions in the supply chain, affecting the overall efficiency and effectiveness of the VMI system. It is essential for companies to establish strong partnerships and implement advanced technologies to overcome these challenges and optimize their VMI operations.

Strategies for Successful VMI Implementation

Implementing a successful Vendor-Managed Inventory (VMI) system requires careful planning and coordination between the vendor and the customer. One strategy for successful VMI implementation is to establish clear communication channels between all parties involved. This includes setting up regular meetings to discuss inventory levels, forecasting, and any issues that may arise. By fostering open communication, both parties can work together to address any challenges and ensure the VMI system runs smoothly.

Another key strategy for successful VMI implementation is to conduct regular performance reviews and evaluations. This allows both the vendor and the customer to assess the effectiveness of the VMI system and make any necessary adjustments to improve efficiency. By analyzing key performance indicators such as fill rates, lead times, and inventory turnover, both parties can identify areas for improvement and work together to optimize the VMI process.

The Conclusion

In conclusion, Vendor-Managed Inventory (VMI) is a strategic approach that can streamline logistics, transport, and shipping processes for businesses. By allowing suppliers to take more control over inventory management, it can help reduce stockouts, improve inventory accuracy, and ultimately drive efficiency in the supply chain. Whether you’re a small business looking to optimize your operations or a large corporation striving for greater cost savings, VMI could be the solution you’ve been looking for. Embracing this innovative approach may just be the key to unlocking your company’s full potential in the world of logistics and shipping. Take the plunge and explore the possibilities of VMI today!